I. Core Specifications & Design Principle

Dimensions:

Rectangular design: 720mm (short side) × 880mm (long side) inner clearance

Total thickness: 190mm (includes cover body, anti-settlement layer, and anti-fall sub-cover)

Structural Innovation:

Unlike traditional "pedestal-type" designs, its spigot-and-socket flange transfers >80% traffic loads directly to the road base—not the brick shaft—preventing perimeter rutting and step settlement.

II. Five Battlefield-Proven Advantages

1. Settlement Elimination

Flange-asphalt integration maintains ≤3mm deviation after 5 years (vs. >15mm for conventional covers).

Tapered seal + water-deflecting rim blocks rain erosion.

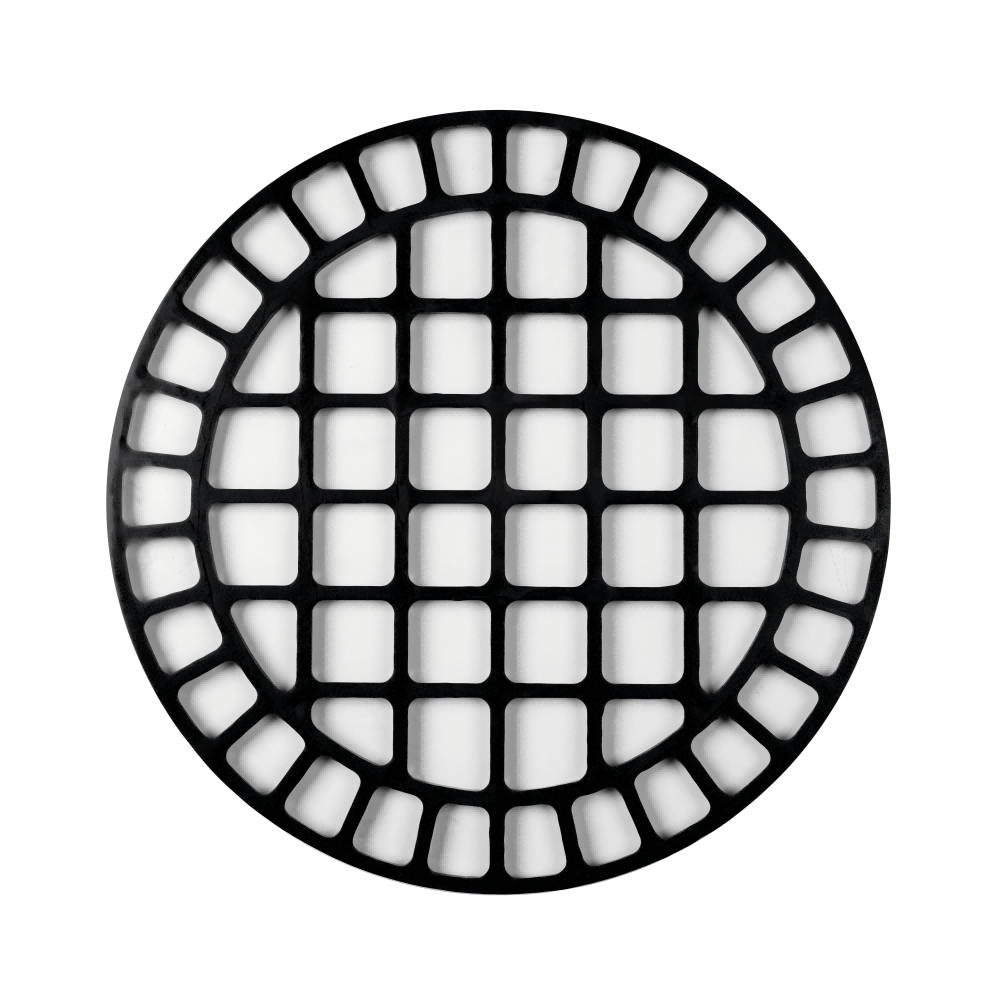

2. 65-Ton Load Mastery

190mm thickness + radial ribs withstand 65-ton loads (exceeding GB/T 23858 D400’s 36-ton standard). Zero deformation under daily container truck traffic.

3. Five-Safeguard Fortress

Noise: ≤43dB with T-rubber damping (ambient-level quiet).

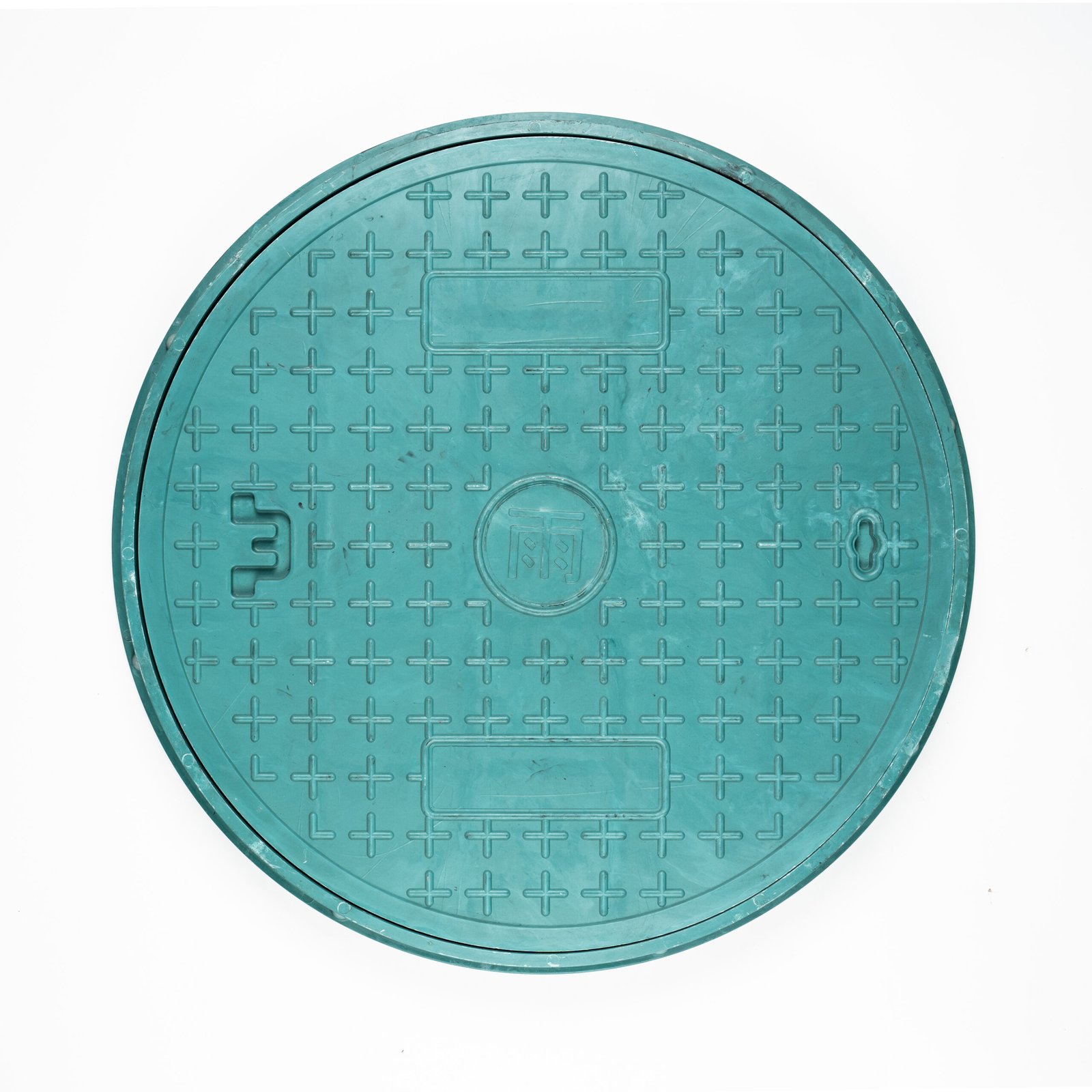

Slip Resistance: Laser-etched waves + micro-knurls (wet friction 0.68 > 0.6 national standard).

Theft-Proof: Zero scrap value + hidden hinge locks (0% theft rate).

Anti-Bounce: Spring arms neutralize wheel impacts.

Anti-Fall: Mechanically locked sub-cover.

4. Extreme Environment Veteran

Hot-dip zinc + epoxy-asphalt coating resists deicers/acid/oil (25+ years salt-spray endurance).

Stable from -40°C (permafrost) to 180°C (steel mill radiation).

5. Smart O&M Revolution

Optional RFID chip stores pipeline depth/attributes/maintenance logs—5x faster inspections via mobile scan.

III. Five Battle-Proven Advantages

1. Settlement Eradication

Frame-asphalt integration maintains surface flatness (≤3mm deviation after 5 years in port freight lanes).

Waterproof edge design blocks rain infiltration.

2. 60-Ton Safety Margin

Deep-pot structure + cross ribs withstand overloads (e.g., 60-ton dump trucks), bending without fracture.

3. Five Safeguards in Action

Noise: ≤45dB in residential areas.

Slip Resistance: 3mm diamond knurls (friction coefficient 0.65 when wet).

Theft Deterrence: Near-zero theft rate (non-recyclable material + hidden locks).

Anti-Fall: Dual-layer protection.

4. Extreme Environment Adaptability

Resists deicers, acid rain, and oil (-30°C to 150°C stable performance).

5. Smart O&M Efficiency

RFID "E-ID": Scannable pipeline data via mobile devices.

Zero Maintenance: 30-year service life; only requires debris flushing.

IV. Critical Installation Protocol

1. Anti-"Soft Foot" Anchoring

Excavate >130cm diameter (frame +20cm margin).

Backfill with steel-fiber C30 concrete (no loose soil).

M20 anchors ≥35cm deep at 15° outward angles.

2. Road Integration Lifeline

Frame top 4–6cm below road surface.

Two-stage asphalt compaction: 140°C initial, 110°C final.

Joints filled with 180°C modified asphalt.

3. Drainage Slope Optimization

5° outward tilt (vs. standard 3°)—30% faster stormwater drainage via 950mm length.

V. Key Applications

Ultra-Heavy Zones: Port container yards, airport taxiways, special vehicle corridors (100-ton capacity).

Sensitive Geology: Soft soil, filled areas prone to settlement.

Smart City Showcases: Core pipeline nodes for municipal IoT.