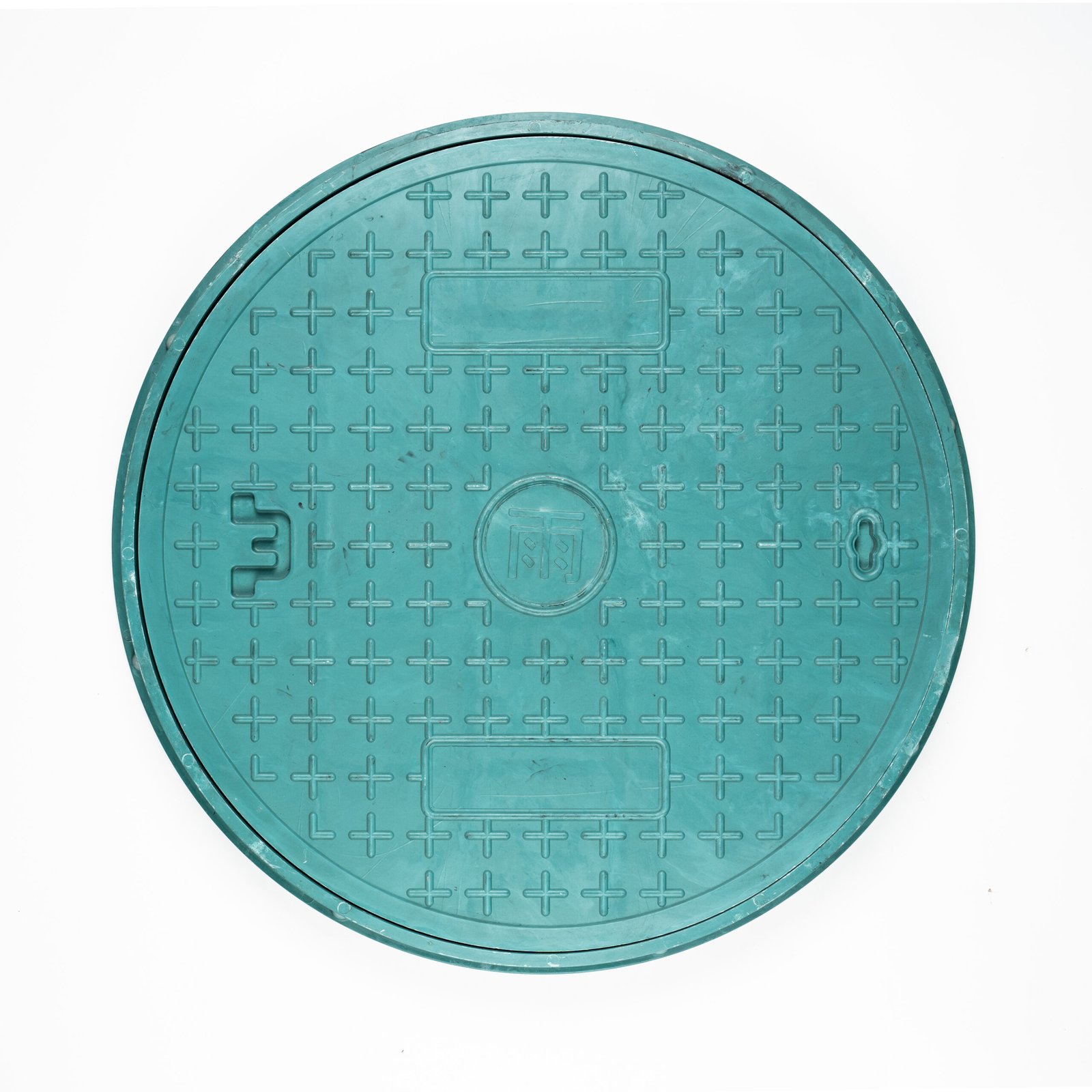

In modern municipal engineering and road construction, inspection chambers serve as critical nodes in the underground pipeline network. Their performance and reliability are directly related to the operational efficiency and safety of the entire city. Traditional inspection chamber materials, such as concrete or cast iron, have long faced challenges including foundation settlement due to excessive self-weight, structural aging from insufficient corrosion resistance, and prolonged construction periods impacting traffic. The Luzhongbao 700x770x70 Composite Circular Inspection Chamber is an innovative solution born precisely to address these industry pain points. Based on high-performance composite material technology and precise engineering design, it aims to provide a lighter, more durable, and more cost-effective strategic choice for urban underground space, representing a new direction in inspection chamber technology development.

The core of this product utilizes a glass fiber reinforced unsaturated polyester resin (BMC/SMC) system, integrally molded through high-temperature, high-pressure compression molding. Its calibrated structural dimensions – nominal inner diameter 700mm, outer diameter 770mm, wall thickness 70mm – are the result of in-depth mechanical simulation and optimization, ensuring exceptional structural stability under complex soil pressure and dynamic traffic loads. The thickened 70mm wall design significantly enhances the product's ring stiffness and impact resistance. This design not only achieves a leap in structural strength but also, due to the inherent advantages of the material, provides excellent chemical corrosion resistance and near-zero maintenance requirements. Its design service life far exceeds that of traditional products, demonstrating unparalleled economy and reliability throughout its entire life cycle.