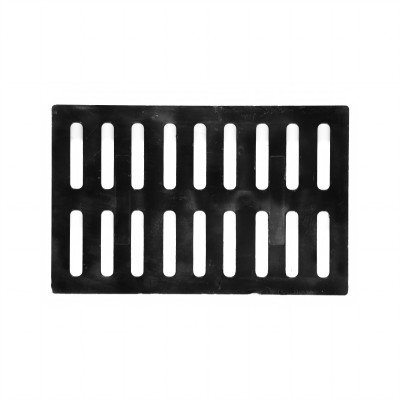

Why Luzhongbao 450×750×40 Ductile Iron Drainage Grate Assembly Has Become the Preferred Choice for Drainage Engineering

In the construction of modern urban drainage systems, drainage grate assemblies, as crucial facilities for road surface drainage, directly impact drainage efficiency, road safety, and service life. Traditional drainage grates often struggle to meet modern urban drainage demands due to problems like insufficient structural strength, low drainage efficiency, and susceptibility to theft. The Luzhongbao 450×750×40 Ductile Iron Drainage Grate Assembly, based on the material advantages of ductile iron and innovative structural design, successfully solves the technical pain points of traditional drainage facilities through scientific drainage hole arrangement and a reinforced support structure, and has now become the ideal choice for projects such as municipal roads and residential area drainage.

This product strictly complies with the GB/T23858 standard and is precision-cast using QT500-7 grade ductile iron. The 450mm × 750mm rectangular dimensions are optimized through fluid dynamics, achieving optimal structural stability while ensuring drainage efficiency. The reasonable 40mm thickness, combined with an internal three-dimensional reinforcement rib network, ensures load-bearing strength while controlling product weight. The surface features a deep anti-slip pattern design and is treated with hot-dip galvanizing, with a zinc layer thickness exceeding 80μm, ensuring long-term performance in humid environments. The unique grate assembly structural design facilitates easy installation and simple maintenance, significantly reducing the whole-life-cycle cost of use.

Material Advantages and Structural Design

The Luzhongbao Grate Assembly selects QT500-7 ductile iron material, with a tensile strength exceeding 500 MPa and an elongation rate over 7%, possessing excellent mechanical properties. Through a unique spheroidization treatment process, the graphite within the material is distributed spheroidally, maintaining the corrosion resistance of cast iron while significantly improving toughness indicators. The product interior features a crisscrossing network of reinforcement ribs, with main rib heights reaching 30mm, supplemented by diagonal support structures, forming a stable spatial load-bearing system that ensures no deformation or breakage under heavy load conditions.

Drainage Performance and Anti-Clogging Design

The drainage hole design of the grate assembly undergoes Computational Fluid Dynamics analysis, employing a gradually varying aperture layout that ensures maximum drainage efficiency while effectively intercepting debris. The total area of the drainage holes accounts for 35% of the grate surface area, far exceeding national standard requirements. The unique inverted trapezoidal channel design causes debris to detach automatically under water flow impact, effectively solving the problem of clogging common in traditional drainage grates. Laboratory tests show that this product maintains 98% drainage efficiency even under rainfall intensity reaching 180 mm/h.

Load-Bearing Performance and Safety Features

The product load-bearing class reaches the D400 standard, with a test load exceeding 400 kN, fully meeting the usage requirements for urban roads. The surface anti-slip pattern consists of raised points and grooves forming a three-dimensional structure, with a friction coefficient exceeding 85 BPN, ensuring pedestrian safety in rainy or snowy weather. The grate body and frame use a three-point buckle connection, ensuring installation stability while facilitating later maintenance and cleaning. A special edge chamfer design effectively avoids noise issues during vehicle passage.

Durability and Anti-Corrosion Treatment

Through dual protection of hot-dip galvanizing and epoxy asphalt coating, the product's corrosion resistance is significantly enhanced. The zinc layer forms a metallurgical bond with the substrate, effectively blocking the erosion of corrosive media. Verified by salt spray tests, the product's service life can exceed 30 years in harsh environments. The grate structure is optimized through Finite Element Analysis, maintaining structural integrity under long-term dynamic loads, greatly reducing the frequency of maintenance and replacement.

Construction Convenience and Economic Benefits

The modular design makes the installation process simple and efficient, with installation time per unit not exceeding 20 minutes. Precise dimensional control ensures a perfect fit with standard frames, requiring no on-site adjustments. From a whole-life-cycle cost analysis, the product's ultra-long service life and extremely low maintenance requirements reduce the comprehensive cost of use by over 40% compared to traditional products. According to engineering statistics, after adopting this grate assembly, the cleaning maintenance frequency decreased from monthly to quarterly, significantly saving operation and maintenance costs.

Application Scenarios and Adaptation Performance

The standard 450×750×40mm size adapts to various municipal drainage needs, being particularly suitable for scenarios like road gutters and residential area drainage. The product can be customized with different surface treatments according to actual needs, meeting the requirements of special environments. Its refined appearance design harmonizes with the surrounding environment, enhancing the overall landscape effect while meeting functional demands.

Summary

The Luzhongbao 450×750×40 Ductile Iron Drainage Grate Assembly, with its excellent material properties, scientific drainage design, reliable load-bearing capacity, and significant economic benefits, has become the preferred solution for modern urban drainage construction. This product not only solves the technical defects existing in traditional drainage facilities but also, with its innovative design concept and exceptional performance, provides reliable assurance for the efficient operation of urban drainage systems. Choosing this product means injecting lasting quality assurance and value return into the engineering project, which is the fundamental reason for its continued recognition in the market competition.