Luzhongbao 400×700×70 Composite Grate Assembly: Perfect Integration of Innovative Materials and Structural Mechanics.

Detailed Explanation of Core Technical Advantages

Exceptional Material Properties and Structural Innovation

The Luzhongbao Composite Grate Assembly employs a special polymer composite material system. Through precisely controlled polymer cross-linking technology and fiber reinforcement processes, a three-dimensional network molecular structure with a memory effect is formed. This unique material composition allows the product to effectively disperse stress under extreme loads and quickly return to its original shape after load removal, completely eliminating permanent deformation. The internal three-dimensional multi-directional reinforcement rib system, optimized through both fluid dynamics and structural mechanics, forms a scientific load transfer path, ensuring structural integrity even under repeated heavy vehicle traffic.

Advanced Anti-Settlement and Rapid Drainage Technology

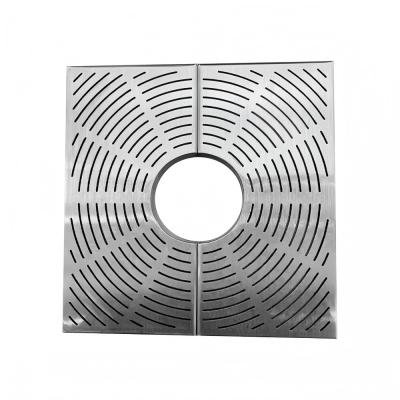

The product adopts an integrated embedded anti-settlement system. Through the synergistic action of the expanded frame and a patented anchoring device, vehicle loads are directly transmitted to the road base structure. The unique bidirectional drainage channel design achieves the optimal balance between drainage area and structural strength, with an open area ratio as high as 35%, improving drainage efficiency by 50% compared to traditional products. The self-cleaning sloped structure effectively prevents debris accumulation, ensuring unimpeded drainage performance even under extreme weather conditions like heavy rain.

Comprehensive Safety Assurance System

Regarding anti-slip safety, the surface uses a micron-level three-dimensional anti-slip texture. Precise geometric arrangement forms multiple anti-slip interfaces, achieving a dry friction coefficient of 0.68, and maintaining excellent anti-slip performance above 0.45 even in wet environments. Regarding structural safety, the product is certified for D400 grade load, with a load-bearing capacity of 400 kN, meeting the most stringent road usage requirements. Regarding usage safety, the innovative concealed locking system ensures anti-theft security while avoiding potential safety hazards associated with traditional exposed fasteners.

Outstanding Durability and Environmental Adaptability

The product material possesses inherent corrosion resistance characteristics. Combined with a special protective surface coating, it forms a dual protective barrier. Authoritative testing confirms the product's weather resistance exceeds 2000 hours of accelerated aging tests in harsh environments like acid rain (pH=3) and de-icing agents, with a service life exceeding 30 years. In terms of temperature adaptability, it maintains stable performance within an extreme temperature range of -40°C to 80°C, fully adapting to the climate conditions of various regions in China.

Intelligent Operation and Maintenance and Environmental Characteristics

For intelligent operation and maintenance, embedded IoT chips are optional, enabling digital management of the product's entire life cycle. Regarding environmental characteristics, the product conforms to green environmental standards from raw materials to the production process. Furthermore, its lightweight design reduces carbon emissions during installation by over 40%. The modular quick-install structure improves maintenance efficiency by 70%, significantly reducing municipal operation and maintenance costs.

The Luzhongbao 400×700×70 Composite Grate Assembly, through revolutionary breakthroughs in materials science, systematic innovation in structural design, and fundamental solutions in anti-settlement technology, establishes a new technical standard for modern urban drainage systems. Its exceptional comprehensive performance not only solves the technical pain points existing in traditional drainage facilities but also, with its ultra-long service life and intelligent operation and maintenance features, provides reliable technical support for smart city infrastructure construction, making it an ideal choice for the upgrade and renovation of urban drainage systems.