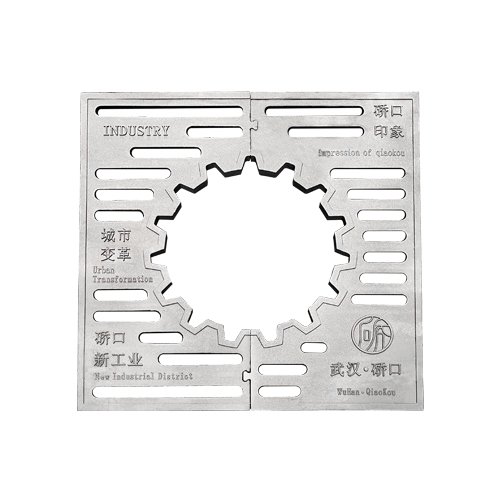

In the construction of modern urban greening and municipal facilities, grass grates, as key nodes connecting underground pipelines and surface greening, directly impact the integrity of the road landscape, the convenience of greening maintenance, and the safety of municipal facilities. Traditional grass grates often face problems such as insufficient load-bearing capacity, susceptibility to corrosion, and poor aesthetics, while ordinary cast iron or cement products struggle to meet the dual needs of ecology and function in modern cities due to material limitations. The Luzhongbao Composite Material Grass Grate, based on high-performance composite materials and innovative structural design, successfully breaks through the technical bottlenecks of traditional grass grates through a scientific formula system and precision production processes, and has now become the ideal choice for projects such as municipal roads, landscape gardens, and residential communities.

This product uses polymer composite materials and a steel reinforcement skeleton, formed in one step through a high-temperature compression molding process, combining excellent mechanical properties with environmental adaptability. Its material characteristics give the product a compressive strength far exceeding traditional cast iron and cement products, with a measured maximum load capacity of up to 54 tons, fully complying with the CJ/T211-2005 standard issued by the Ministry of Construction. The unique structural design not only achieves lightweight (weighing only one-third of cast iron products) but also flexibly adapts to various greening scenario needs through modular combination and colorable characteristics. Furthermore, the material's lack of scrap value fundamentally solves the theft problem, while the corrosion resistance and anti-aging properties ensure long-term stable use of the product in environments from -50°C to 150°C, with a design life exceeding 30 years.

Material Advantages and Process Innovation

The core advantage of the Luzhongbao Grass Grate stems from its innovative materials science and manufacturing process. The product matrix uses polymer synthetic materials (such as SMC resin), and the reinforcement system is achieved through directionally distributed glass fibers and a steel reinforcement skeleton. This material combination gives the product high tensile strength and strong impact resistance, with mechanical properties comprehensively superior to traditional cast iron and cement products. The manufacturing process uses computer-controlled high-temperature compression molding technology. Precisely regulated temperature and pressure parameters ensure thorough material curing and a dense, uniform internal structure, effectively avoiding common porosity and defect issues in traditional cast products.

The environmental adaptability of the material further enhances the product's comprehensive value. The inherent corrosion resistance of the composite material enables it to resist erosion from acids, alkalis, rainwater, and de-icing agents in the soil, with an anti-aging grade reaching Level 3 or above. Simultaneously, the product surface can achieve customized colors by adding color paste, allowing it to blend harmoniously with the surrounding green landscape while distinguishing functional uses through color, improving the management efficiency of municipal facilities.

Structural Design and Functional Characteristics

1.Balance of Lightweight and High Strength:

The product achieves weight minimization while ensuring load-bearing capacity by optimizing the internal reinforcement rib network. Its weight is only one-third of similar cast iron products, significantly reducing the difficulty of transportation, installation, and maintenance.

2.Precise Fit Clearance:

The high-temperature compression molding process controls the cover-frame gap within an extremely small range, effectively overcoming problems like "movement, bouncing, and noise" common in traditional covers, significantly improving road traffic comfort.

3.Ecological Compatibility Design:

The hollowed-out structure of the grass grate ensures soil water and air permeability, promoting healthy plant root growth, while also avoiding soil compaction in greening areas through load dispersion design.

Safety Performance and Anti-Theft Characteristics

The Luzhongbao Grass Grate achieves multiple breakthroughs in safety:

Anti-theft Design: The composite material has no scrap value, fundamentally preventing theft. Some products also add locking structures to further ensure the safety of internal facilities.

Anti-slip and Anti-fall: The surface pattern design incorporates anti-slip function, with a friction coefficient exceeding 80 BPN, ensuring pedestrian safety in rainy or snowy weather.

Stability Performance: The precise structural design prevents the product from shifting or bouncing under vehicle traffic, effectively avoiding potential risks to pedestrians and traffic.

Durability and Economic Value

Through dual optimization of thermal stability and corrosion resistance, the product maintains stable performance even in extreme environments. Tests show it can be used normally within a temperature range of -50°C to 150°C, and its anti-aging index reaches Level 3 or above, with a design service life exceeding 30 years.

From a whole-life-cycle cost analysis, although the initial investment may be comparable to traditional products, its ultra-long service life and extremely low maintenance requirements significantly reduce the comprehensive cost of use. According to engineering statistics, after adopting this grass grate, the replacement frequency due to theft, corrosion, or damage is reduced by over 80%, effectively saving municipal maintenance funds.

Application Scenarios and Adaptation Performance

The diverse specifications of the Luzhongbao Grass Grate enable it to flexibly adapt to various scenarios:

Urban Road Green Belts: Heavy-duty products are suitable for greening areas on main and express lanes, with load-bearing grades meeting vehicle traffic requirements.

Residential Communities and Landscape Gardens: Standard and light-duty products can be used in areas like sidewalks and community greenery, achieving landscape integration through color customization.

Special Greening Scenarios: Modular design supports customized sizes, meeting special needs like irregular tree pits and slope greening.

Summary

The Luzhongbao Composite Material Grass Grate, with its innovative material formulation, scientific lightweight structure, exceptional safety performance, and long-term economy, has become the preferred solution for modern urban greening construction. This product not only solves the technical defects of traditional grass grates in terms of load-bearing capacity, durability, and anti-theft performance but also, through its eco-friendly design and flexible adaptation characteristics, provides reliable guarantees for the coordinated development of urban greening and municipal facilities. Choosing this product means injecting sustainable value return and quality assurance into the engineering project, which is the fundamental reason for its continued recognition in the market competition.