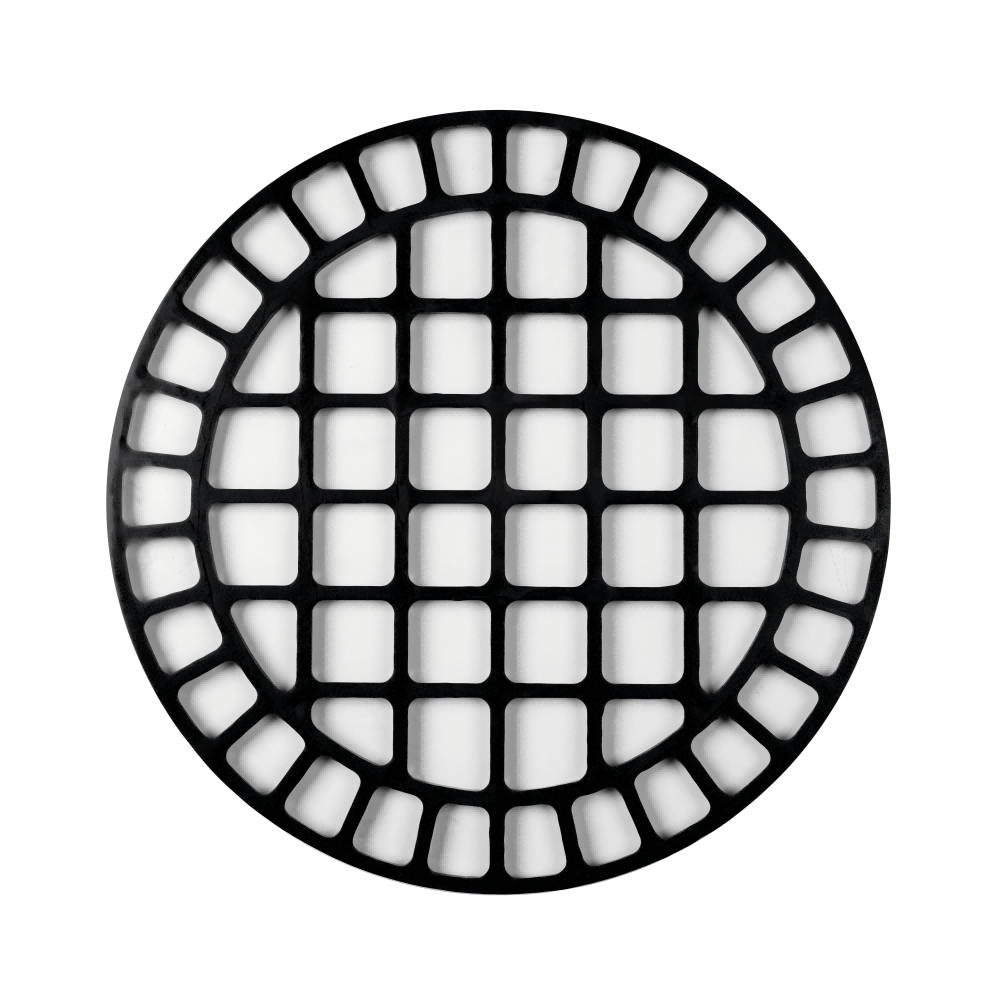

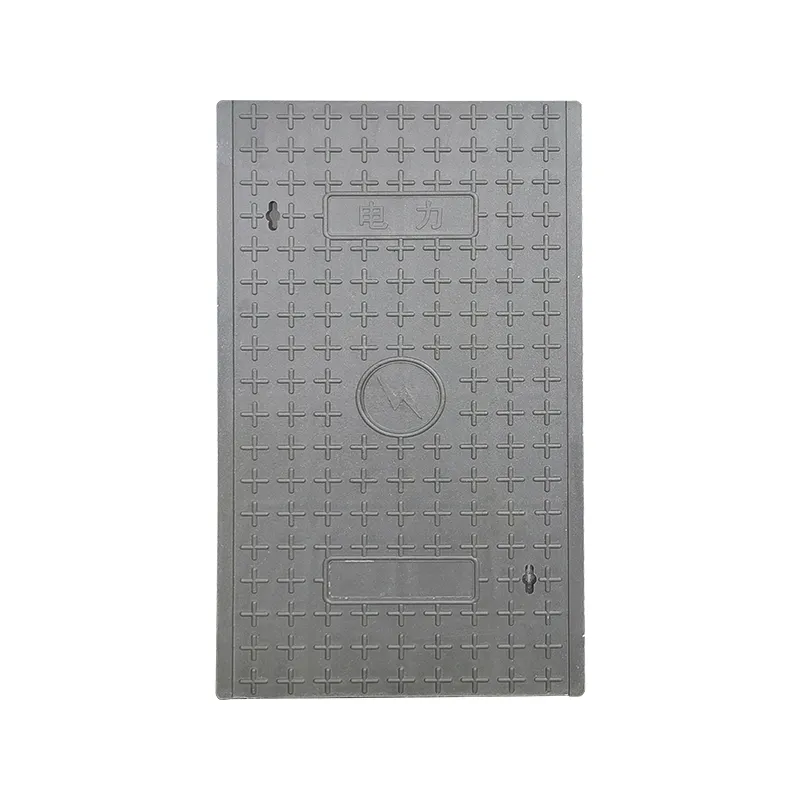

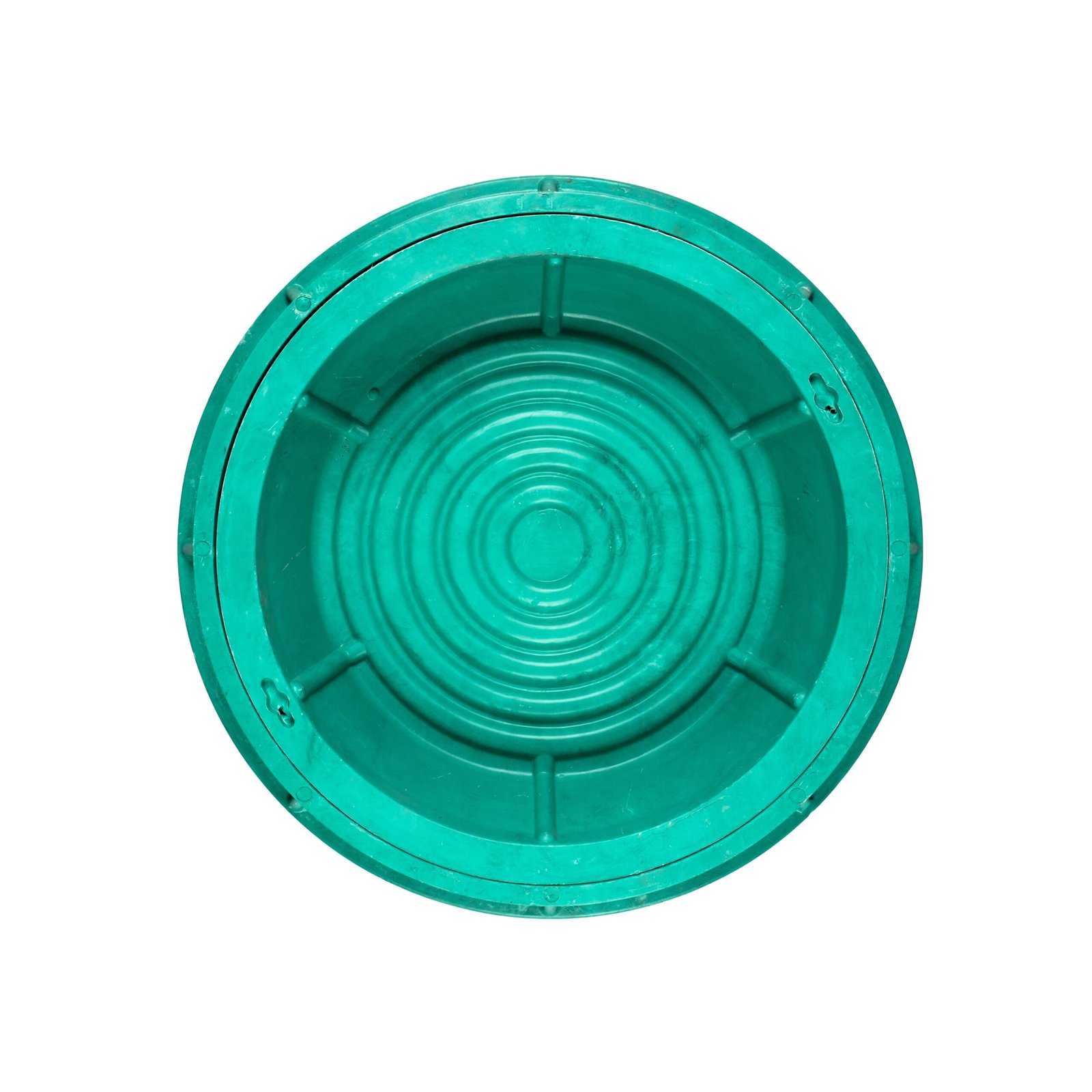

Composite power cable covers are advanced protective components manufactured from polymer composite materials (e.g., resin, fiberglass) using high-temperature, high-pressure molding processes. Designed for cable trenches, substations, municipal roads, and other infrastructure, they provide critical protection for underground cables and equipment. By integrating material hybridization technology, these covers combine the strengths of diverse components, replacing traditional cast iron or concrete covers while balancing functionality, safety, and cost-effectiveness.

Composite power cable covers achieve an optimal balance between performance and economy through material innovation. Their high strength, corrosion resistance, and lightweight properties make them essential components in modern power infrastructure. With ongoing advancements in composite materials (e.g., carbon fiber-reinforced resins), their performance will further improve, expanding their application scope.

x30-铸铁圆井盖1-scaled.jpg)