Core Advantages of HDPE Reinforced Pipes

1. Exceptional Physicochemical Properties

- Corrosion Resistance: Our HDPE reinforced pipes resist acids, alkalis, salt spray, oils, and microbial erosion without the need for additional coatings. These pipes offer a service life of 50+ years, far exceeding the 20-30 years of traditional concrete pipes.

- Impact Resistance & Flexibility: These pipes maintain flexibility even at -60°C, tolerating ground settlement or seismic deformation with a bending radius ≥15× pipe diameter, making them ideal for areas prone to soil movement or earthquakes.

- Abrasion Resistance: The smooth interior of the pipe (roughness coefficient 0.009) minimizes friction and scaling, ensuring efficient fluid flow and longer-lasting performance.

2. Superior Structural Mechanics

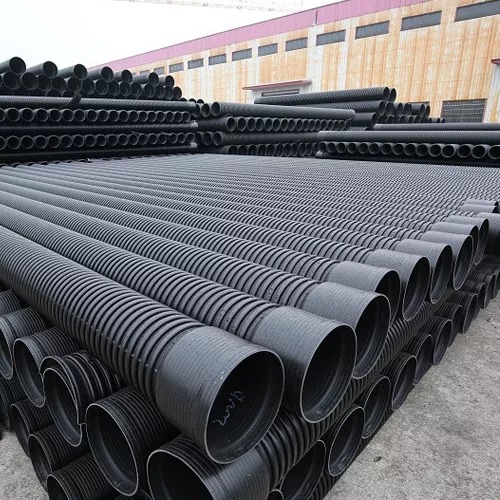

- High Ring Stiffness: Featuring a corrugated exterior, our HDPE pipes offer SN4-SN16 ring stiffness, able to withstand deep burial loads and heavy traffic pressure (≥800 kN/m²).

- Lightweight & Cost-Effective: With a density of 0.95 g/cm³, these pipes weigh only 1/10 of concrete pipes, significantly reducing transportation and installation costs by up to 50%.

- Quick and Easy Installation: Thanks to electrofusion sockets or rubber ring joints, our HDPE pipes install 3x faster than traditional pipes, ensuring zero leakage and minimal downtime.

3. Eco-Economic Benefits

- 100% Recyclable: Our HDPE pipes are fully recyclable, offering 70% lower carbon emissions compared to concrete production. These pipes are fully compliant with LEED and BREEAM sustainability standards.

- Cost Efficiency:

- 40% lower installation costs due to reduced machinery needs.

- 90% lower maintenance costs since our pipes do not require dredging or anti-corrosion treatments.

4. Multi-Scenario Adaptability

- Temperature Range: Designed for extreme climates, these pipes perform efficiently in temperatures from -60°C to +60°C, making them suitable for industrial wastewater and harsh environments.

- Full Diameter Coverage: Available in sizes from DN200 to DN3000, these pipes cover a wide range of applications, from branch lines to main networks.

Typical Applications for HDPE Reinforced Pipes

1. Municipal Engineering

- Ideal for stormwater and sewage mains (DN800-DN3000).

- Efficient for roadside drainage and tunnel seepage systems.

2. Agriculture & Hydraulics

- Perfect for farm irrigation channels and reservoir conduits.

- Ideal for aquaculture and water circulation pipelines.

3. Industrial Use

- Suitable for chemical plant acid/alkali wastewater discharge.

- Ideal for mining tailings transport, providing abrasion resistance for harsh industrial environments.

4. Telecom & Power

- Reliable as fiber optic cable conduits, resistant to rodents and compression.

- Safe for underground cable channels in substations.

Applicable Scenarios for HDPE Reinforced Pipes

1. Municipal Infrastructure

- Efficient solutions for underground drainage, sewage systems, rainwater collection, water supply, and ventilation networks.

2. Utility Protection

- Protect vital infrastructure with conduits for power cables, fiber optics, and telecom lines, ensuring long-term reliability and performance.

3. Industrial & Agricultural Solutions

- Acid/alkali-resistant irrigation systems offer up to 70% water savings and 13.9% energy reduction.

- Rural wastewater management and eco-friendly agricultural pipelines contribute to sustainable farming practices.

Why Choose HDPE Reinforced Pipes?

HDPE reinforced pipes offer exceptional durability, cost efficiency, and sustainability across a variety of applications. Their corrosion resistance, impact flexibility, low maintenance needs, and quick installation make them a superior choice for infrastructure projects. Whether for municipal, industrial, or agricultural use, these pipes are built to perform in the most demanding environments. Choose HDPE reinforced pipes for a reliable, eco-friendly, and cost-effective solution to your pipeline needs.

Contact us today to learn more about how HDPE reinforced pipes can optimize your infrastructure project!