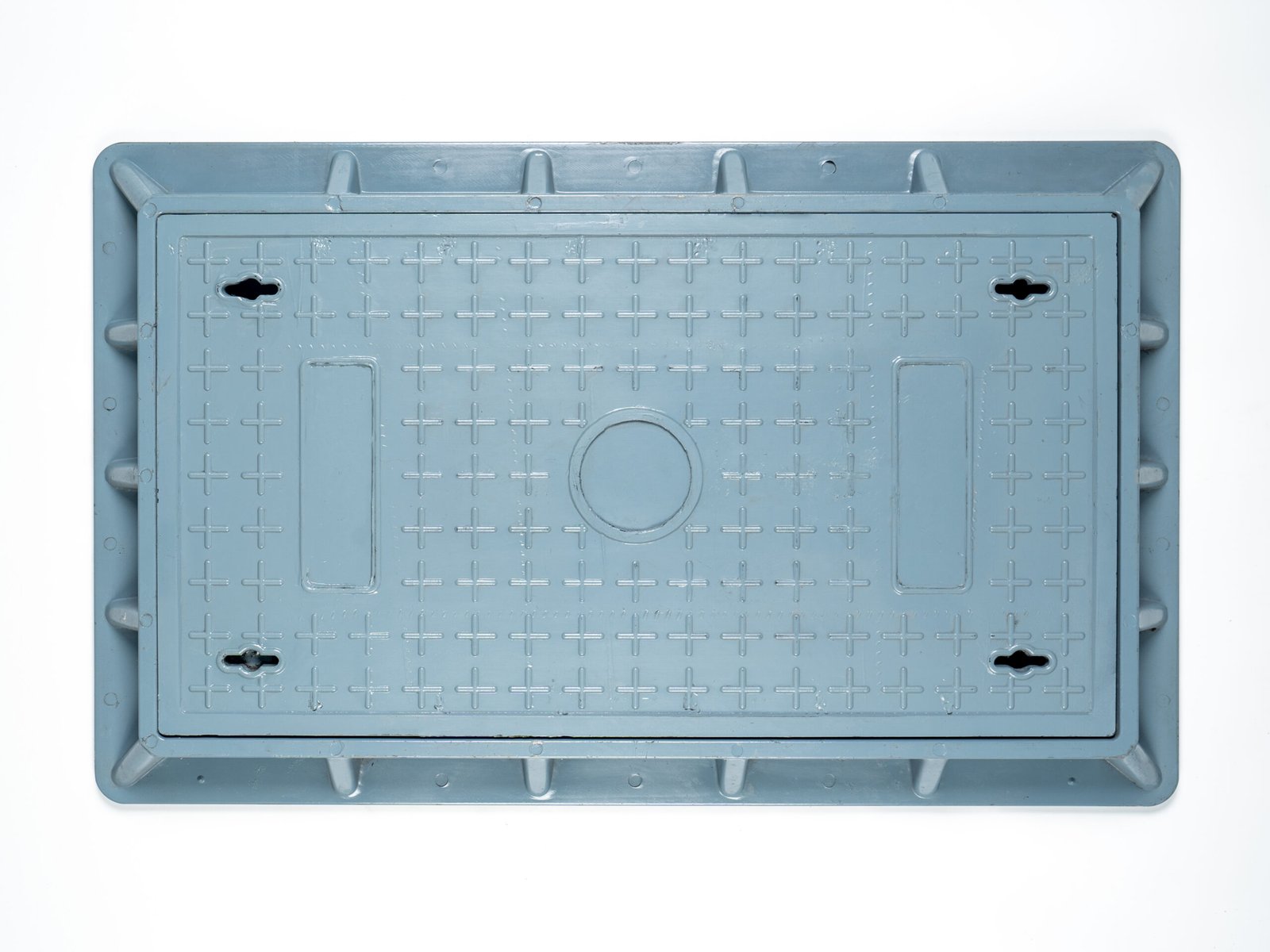

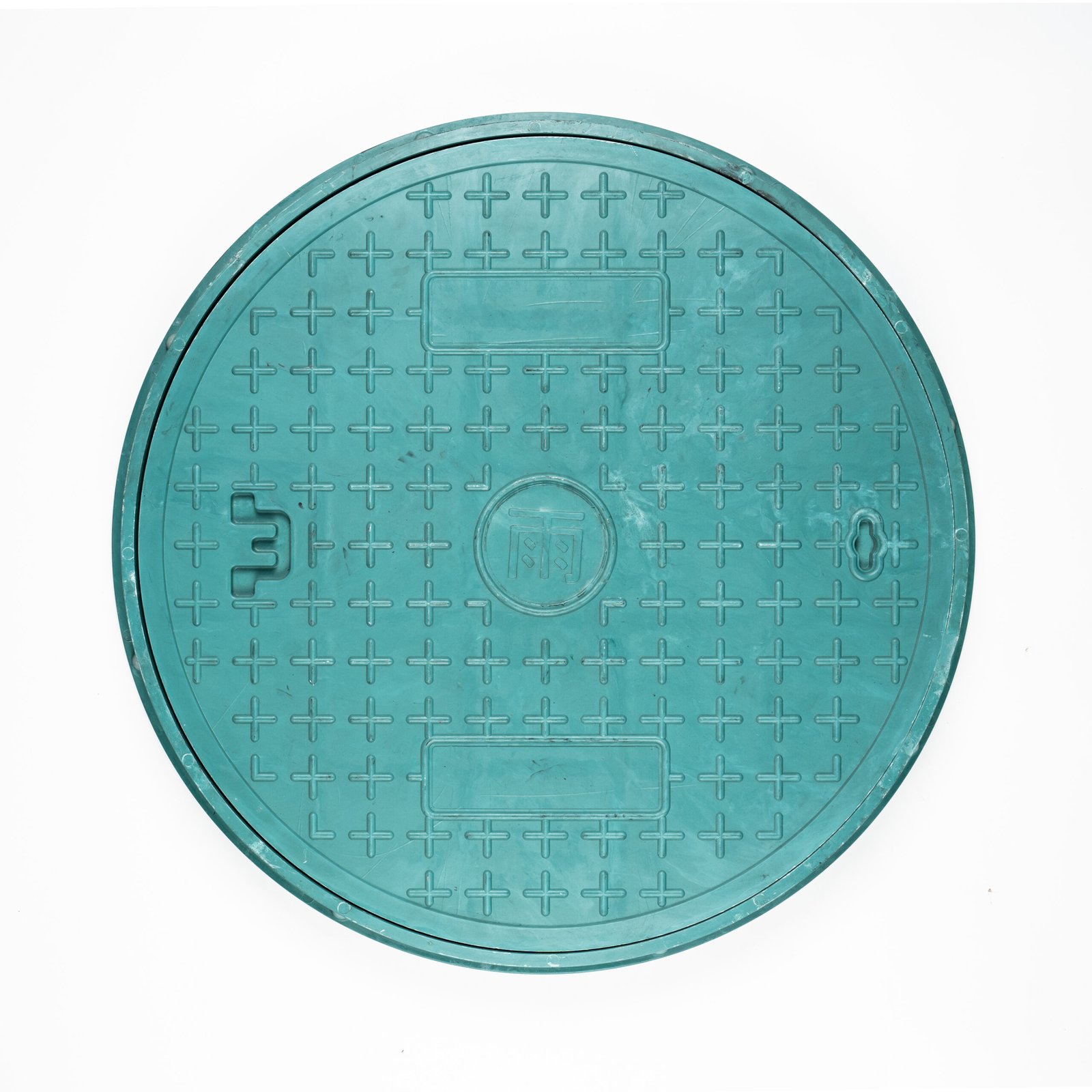

Artistic color-coated steel manhole covers are functional decorative covers made from galvanized steel or aluminum alloy substrates with colored coatings (polyester, fluorocarbon, or PVDF) applied via spray coating, laminating, or digital printing. Combining vibrant aesthetics, lightweight design, and rapid customization, they offer "low-cost artistry" and "industrial-grade durability," ideal for urban landscape enhancement, cultural tourism landmarks, and commercial complexes.

Validated in cultural tourism projects in Xiamen and Chengdu, these covers integrate lightweight design, visual appeal, and affordability, making them a prime solution for urban renewal. Future integration with smart interactive features will expand their applications. Key selection criteria include coating quality, load compatibility, and cultural IP integration to avoid prioritizing aesthetics over functionality, ensuring dual utility and aesthetic value.