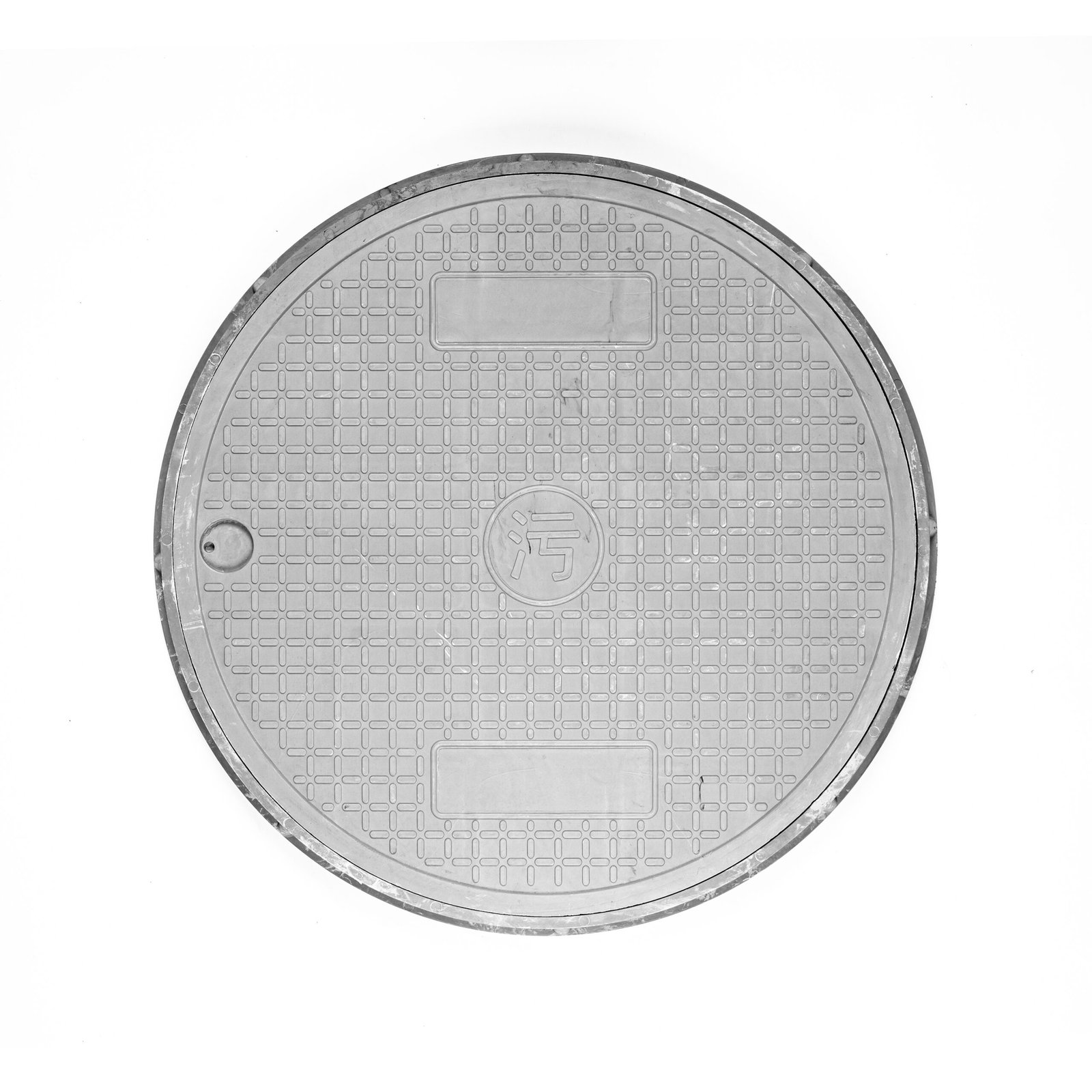

This cover eradicates settlement through spigot-flange load dispersion, leveraging QT600-3/QT500-7 super-Ductile Cast Iron for 60-ton protection. Its 190mm-thick structure integrates an anti-fall sub-cover and smart sensor module, fusing physical safety with digital management. Crucially, zinc-fluorocarbon anti-corrosion extends service life beyond 40 years in harsh environments, while modular installation slashes road occupation time—redefining the balance between urban safety and operational efficiency.

750×950×190 Ductile Cast Iron Anti-Settlement Manhole Cover

-

Product Features:

Ultra-High Load Capacity,30-Year Anti-Corrosion,Zero-Settlement Patented Structure

-

Inquire Now

- hubeiluzhongbao@gmail.com

-

Product Description

I. Breakthrough Anti-Settlement Design

1. 3D Load Dispersion System

Spigot-Flange Base: ≥150mm-wide flange embeds into asphalt base, transferring >85% traffic loads directly to road strata (eliminating "bowl settlement").

Pre-Compressed Elastic Layer: High-density rubber buffers compensate for subgrade deformation, maintaining ≤0.5mm road-cover leveling.

2. Triple Anti-Displacement Locking

Anchor Matrix: Four M20 ground anchors (500mm deep, 120° cross-angled) bolt into reinforced concrete.

Self-Adjusting Spring Latches: Eight spring-steel locks engage frame grooves to resist horizontal shear.

Hinge Safeguard: 18mm stainless hinge + anti-detention clip prevents impact-induced separation.

II. Five Battlefield-Proven Advantages

1. Settlement Elimination

Flange-asphalt integration maintains ≤3mm deviation after 5 years (vs. >15mm for conventional covers).

Tapered seal + water-deflecting rim blocks rain erosion.

2. 65-Ton Load Mastery

190mm thickness + radial ribs withstand 65-ton loads (exceeding GB/T 23858 D400’s 36-ton standard). Zero deformation under daily container truck traffic.

3. Five-Safeguard Fortress

Noise: ≤43dB with T-rubber damping (ambient-level quiet).

Slip Resistance: Laser-etched waves + micro-knurls (wet friction 0.68 > 0.6 national standard).

Theft-Proof: Zero scrap value + hidden hinge locks (0% theft rate).

Anti-Bounce: Spring arms neutralize wheel impacts.

Anti-Fall: Mechanically locked sub-cover.

4. Extreme Environment Veteran

Hot-dip zinc + epoxy-asphalt coating resists deicers/acid/oil (25+ years salt-spray endurance).

Stable from -40°C (permafrost) to 180°C (steel mill radiation).

5. Smart O&M Revolution

Optional RFID chip stores pipeline depth/attributes/maintenance logs—5x faster inspections via mobile scan.

III. Project Economics

1. Zero-Maintenance Longevity

10+ years between repairs; 75% lower annual maintenance cost.

Self-lubricating latches/seals never require replacement.

2. Rapid Installation

Template-guided positioning (<30 mins; ±1mm elevation accuracy).

Hot-embedded asphalt integration—no curing delay.

IV. Critical Installation Protocol

1. Anti-"Soft Foot" Anchoring

Excavate >130cm diameter (frame +20cm margin).

Backfill with steel-fiber C30 concrete (no loose soil).

M20 anchors ≥35cm deep at 15° outward angles.

2. Road Integration Lifeline

Frame top 4–6cm below road surface.

Two-stage asphalt compaction: 140°C initial, 110°C final.

Joints filled with 180°C modified asphalt.

3. Drainage Slope Optimization

5° outward tilt (vs. standard 3°)—30% faster stormwater drainage via 950mm length.

V. Key Applications

Ultra-Heavy Zones: Port container yards, airport taxiways, special vehicle corridors (100-ton capacity).

Sensitive Geology: Soft soil, filled areas prone to settlement.

Smart City Showcases: Core pipeline nodes for municipal IoT.

Epilogue: Twenty-Five Years On, It Remains the Ultimate Answer for Heavy-Duty Roads

Through two decades of roaring wheels, I’ve witnessed countless covers buckle under overloads and installed this city’s first anti-settlement system. The 750×950×190 cover stands as the "bedrock of heavy-load routes" by taming settlement with its tray structure, fortifying safety through five safeguards, and achieving half-century longevity at minimal lifecycle cost. When embedded sensors transmit their first health data, we’ll shift from reactive fixes to proactive guardianship—beneath this black rectangle pulses the resilient heartbeat of the city.

Luzhongbao

High Precision from Luzhongbao!

Provide your needs

Request a Quote

If you have any questions

please feel free to contact us.

Focus on the field of caterpillar mobile crushing and screening, so that solid waste recycling more efficient!