Through material innovation (fiberglass reinforced resin), process advancement (high-temperature compression molding), and structural optimization (dual-leaf locking), this cover significantly outperforms traditional designs in load reliability, environmental durability, operational economy, and public safety. Its 75mm thickened design enhances deformation resistance—particularly suited for heavy-traffic zones—representing the ideal solution for modern municipal infrastructure pursuing lightweight construction, extended service life, and zero maintenance.

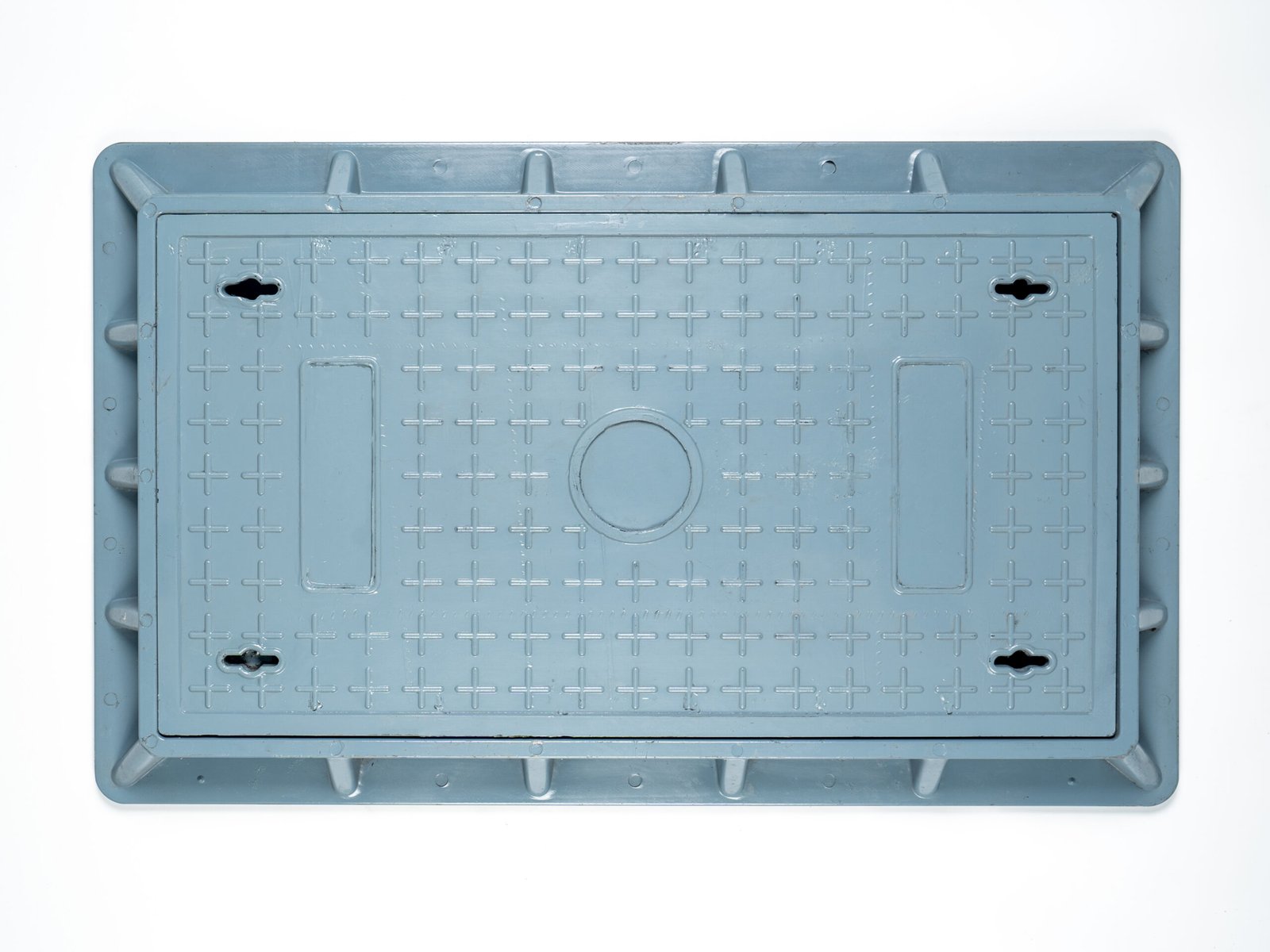

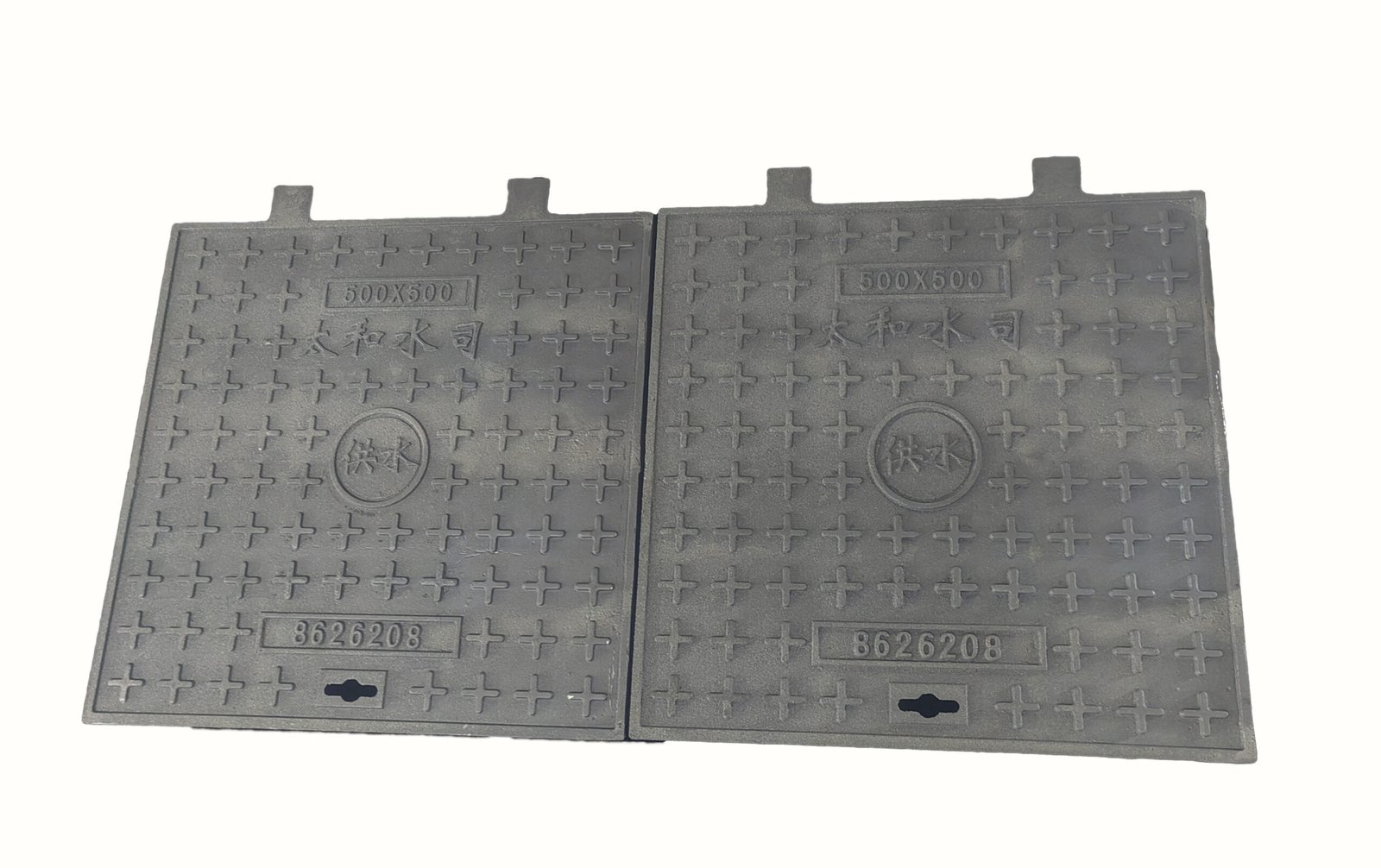

620×1000×75 Composite Rectangular Manhole Cover

-

Product Features:

Excellent Strength and Load-Bearing Capacity,Outstanding Corrosion Resistance,Easy Installation

-

Inquire Now

- hubeiluzhongbao@gmail.com

-

Product Description

I. Structural Analysis: Purpose-Built Non-Standard Dimensions

- Core Material: Unsaturated polyester resin + fiberglass reinforcement, molded in one high-pressure cycle. Metal-free construction eliminates scrap value, inherently solving theft risks.

- Dimensions: 620mm (W) × 1000mm (L) × 75mm (H) – optimized for elongated pits (e.g., congested utility corridors). The 75mm thickness boosts structural stability.

- Process Innovation: Layered lamination bonds the wear-resistant surface (quartz-embedded) with internal reinforcement (continuous long fibers) for crack/compression resistance.

II. Six Core Advantages

1. Robust Load Capacity & Safety Redundancy

Despite narrower width, the 75mm thickness + bowl-shaped base efficiently disperses pressure. Tested ultimate load >40 tons – reliably serves fire lanes/freight entrances with zero long-term deformation.

2. Extreme Environment Resilience

Resin-fiber composite inherently resists acids, coastal salt spray, and -30°C freeze-thaw cycles. 25+ year lifespan – far exceeding cast iron (≈10 years).

3. Lightweight & Installation Efficiency

1/3 the weight of equivalent cast iron covers (50-60kg). Enables two-person installation in confined spaces (e.g., alleys, garages), cutting repair time by >50%.

4. Noise Reduction & Slip Resistance

Eliminates metal clanging noise during vehicle passage. 3D anti-slip texture maintains high wet-surface friction for pedestrian/e-bike safety.

5. Watertight Seal for Subsurface Protection

EPDM gasket + precision fit prevents water infiltration – critical for meter pits/low-voltage chambers where moisture compromises equipment.

6. Custom Aesthetics & Functionality

Integral coloring (non-painted), stone/wood textures, and utility markings (“Gas”, “Comms”). Blends seamlessly into scenic/historic districts.

III. Why Non-Standard Dimensions Are Advantageous?

This 620×1000 rectangle solves specific engineering challenges:

Space-Constrained Installations: Fits narrow wall gaps or pipe trench corners where square covers fail.

Equipment Alignment: Covers laterally arranged valves/meter groups with minimal excavation.

Cost Efficiency: Avoids custom concrete formwork – 20% lower total cost vs. cast-in-place alternatives.

IV. Installation & Maintenance Guidelines

Base Preparation: 400mm-wide concrete collar (≥10-day curing)

Paving Protection: Cover surface during asphalt laying to prevent bonding

Backfill Protocol: Compact medium-coarse sand in layers to frost depth. *No direct mechanical compaction on cover.*

V. Eco-Compatibility & Urban Integration

Sustainable Manufacturing: 1/4 energy consumption vs. cast iron + recyclable scrap

Aesthetic Customization: Anti-slip patterns, logos, or regional symbols; RAL color matching for landscape harmony

Conclusion: Compact Size, Macro Impact

Though non-standard, the 620×1000×75 composite cover delivers exceptional adaptability through high load capacity, corrosion resistance, and lightweight design. As a field engineer, I’ve witnessed its effectiveness in narrow-lane repairs, chemical-zone safety, and scenic-area integration. With growing urban renewal demands, such tailor-made composite covers will become vital for precision infrastructure development.

Luzhongbao

High Precision from Luzhongbao!

Provide your needs

Request a Quote

If you have any questions

please feel free to contact us.

Focus on the field of caterpillar mobile crushing and screening, so that solid waste recycling more efficient!