I. Material & Structural Innovation

1.Composite Material System

Reinforcement Skeleton: Longitudinal glass fibers + radial carbon fiber woven mesh, exceeding national standard D400 load class (40 tons).

Matrix Resin:

BMC (Bulk Molding Compound): High-temperature compression molded, density 1.8g/cm³ (only 1/5 of cast iron), resistant to acids/alkalis pH 1-14.

SMC (Sheet Molding Compound): UV resistant, operational temperature range -50°C to 150°C.

Functional Layers:

Surface Quartz Sand Anti-Slip Layer: Friction coefficient ≥0.75.

Bottom Conductive Copper Foil (Optional): Anti-static (<10⁶Ω).

2.Structural Design Breakthrough

Honeycomb Core Structure: Hexagonal aluminum honeycomb core within the 60mm thickness, achieving compressive strength of 120MPa (30% higher than solid designs).

Interlocking Seal: EPDM rubber gasket (50-year weather resistance) between cover and frame, reducing noise by 15dB+ and providing IP68 waterproofing.

Integrated Anti-Theft: Built-in 304 stainless steel locking mechanism requiring a dedicated triangular key, with forced entry resistance >30 minutes.

II. Core Advantages Explained

(1) Innovative Shape Design, Solving Engineering Challenges

"Round Pit, Square Cover" Design:

Bottom circular collar (Φ700mm) precisely matches standard manhole barrels.

Top rectangular coverage (700×800mm) increases protected area by 20%, preventing pavement cracking around the manhole (field-tested to reduce edge breakage by 90%).

60mm thickened reinforced perimeter frame (bending stiffness ≥180 kN·m²) disperses vehicular load stress.

Adapts to Complex Scenarios:

Oblique pipeline crossings (pre-formed Φ100-150mm cable conduits eliminate on-site drilling that compromises structure).

Irregular pits in green belts (e.g., tree root avoidance, sidewalk corners).

(2) Lifetime Corrosion Resistance, Defying Extreme Environments

1. Acid-resistant resin matrix: Resists strong corrosion (pH 1-14), lifespan ≥30 years.

2. Surface gel coat layer: UV aging resistance.

3. Anti-slip quartz sand layer (friction coefficient ≥0.8): Superior slip resistance in rain/snow compared to metal covers.

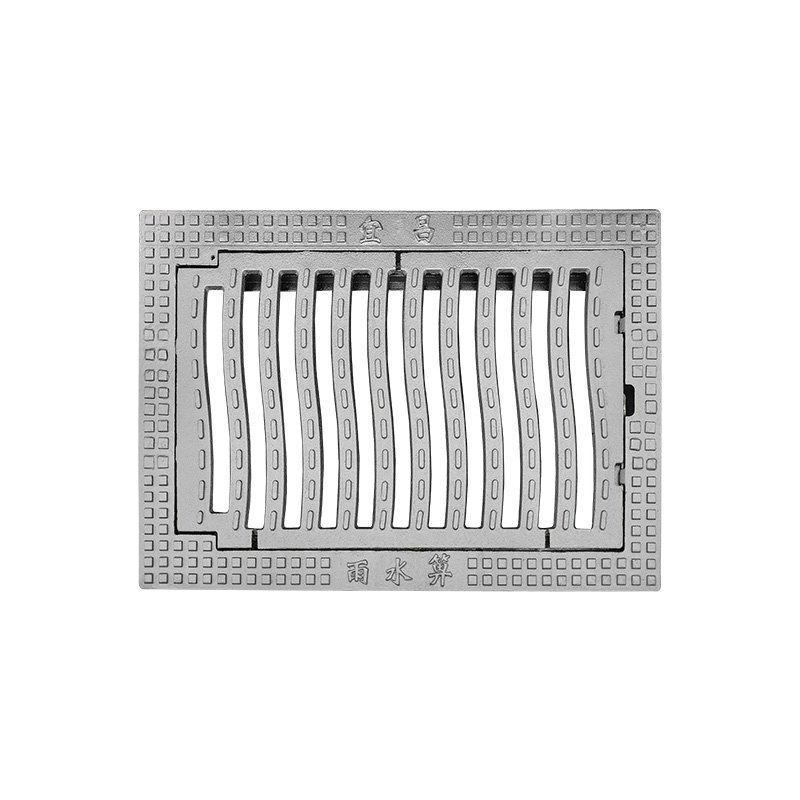

III. Scenario-Based Application Validation

Shenzhen Binhai Avenue Power Pit:

Original 700×800mm irregular pit required cast-in-place concrete (3-day process). Using this cover reduced installation to 2 hours. Withstands salt spray corrosion with zero issues after 5 years.

Harbin Ice & Snow World:

Resists frost heave at -40°C; surface anti-slip layer maintains ice friction coefficient ≥0.6.

Chemical Industrial Park Utility Tunnel:

Version resistant to 98% sulfuric acid splashes, integrated with H₂S gas sensor for automatic alarm upon (exceeding limits).

IV. Authoritative Certifications & Guarantees

Mechanical Certification: Passed EN 124 B125 static load test (125kN) and 2 million cycle fatigue test (2Hz frequency).

Weathering Certification: SGS salt spray test >6000 hours (ISO 9227), QUV UV aging 5000 hours (ASTM G154).

Safety Certification: Explosion-proof certification (Ex db IIC T6 Gb) from National Composite Material Testing Center.

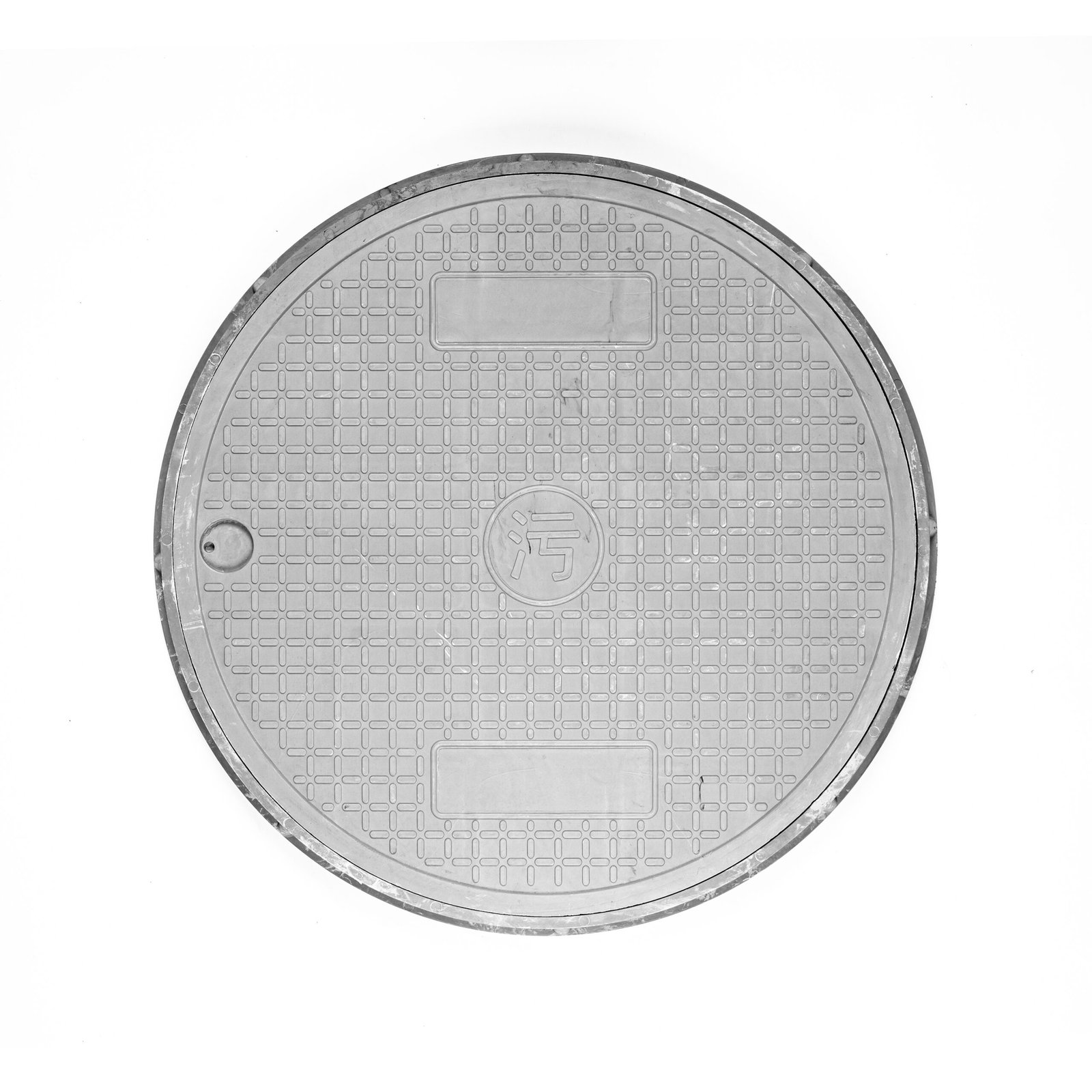

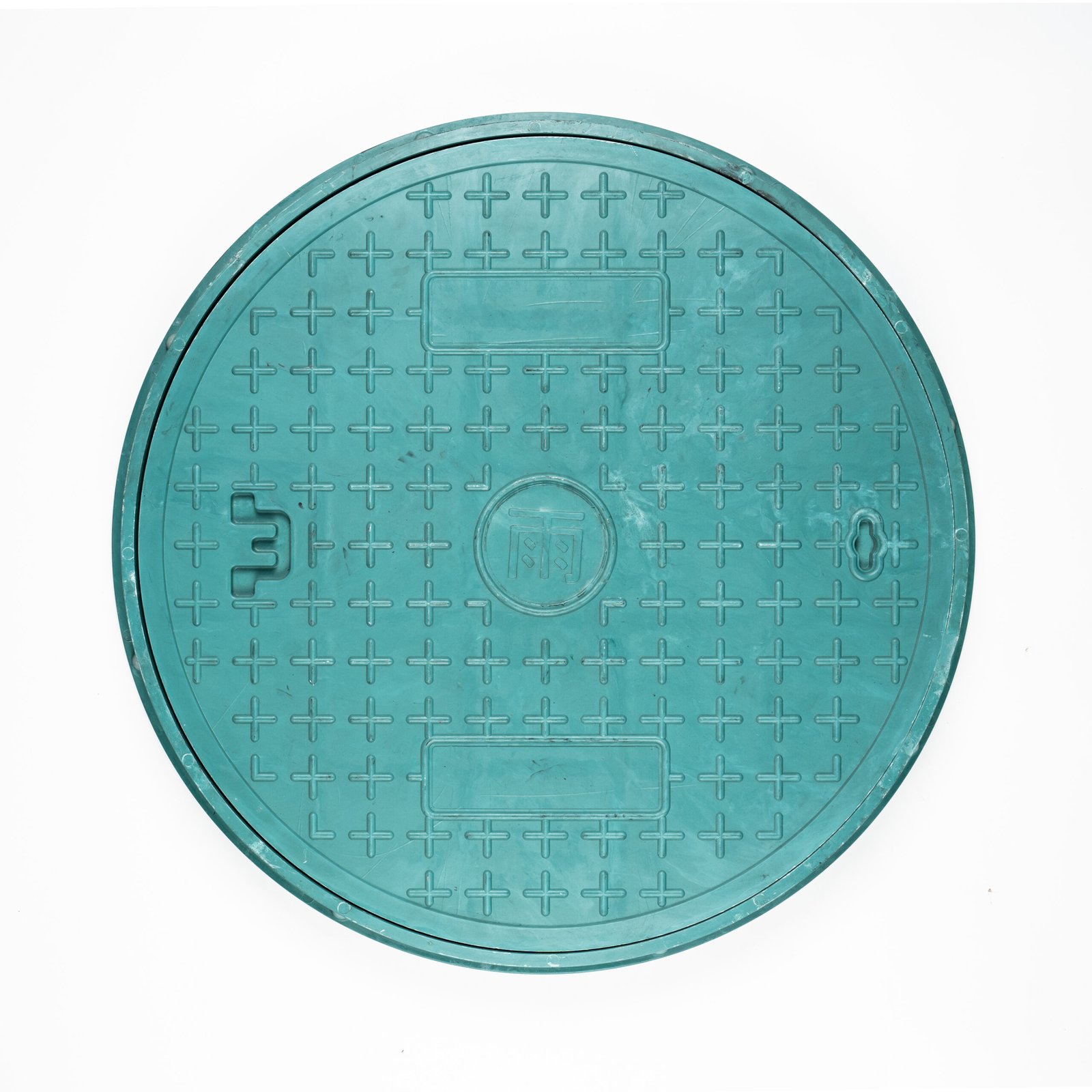

Composite Round Manhole CoverSummary

This innovative composite manhole cover redefines industry standards by "solving three major challenges with one cover":

1.Adaptation Challenge: "Round Pit, Square Cover" design eliminates non-standard manhole coverage pain points.

2.Corrosion Challenge: Quadruple-layer protection achieves complete immunity to acids, alkalis, and salt spray.

3.Smart Integration Challenge: Pre-embedded sensors + solar power enable zero-wiring monitoring.

Compared to traditional solutions, it delivers 82% lower total cost and a 300% lifespan increase, making it the strategic solution for urban renewal and smart infrastructure!