I. Technical Features

1. Material & Manufacturing

- - Base Material: QT500-7 Ductile Cast Iron

- - Tensile strength ≥500 MPa (2× higher than ordinary steel)

- - Elongation ≥7% | Impact toughness ≥15 J/cm²

Rare Earth-Magnesium Nodularization:

- - Nodularization rate ≥90% (per GB/T 9441)

Triple-Layer Corrosion Protection:

- - Zinc spray coating (≥100μm) + Epoxy resin layer + Zn-Al sealant

- - Salt spray resistance ≥3,000 hrs (ASTM B117)

2. Functional Extensions

- - Smart Fall-Prevention System: Optional load sensor with automatic alarm (>150 kg overload)

- - Extreme Environment Resilience: Operational range -50°C to 150°C (validated in Harbin’s arctic cold & Hainan’s tropical heat)

II. Core Competitive Advantages

1. Intrinsic Safety Enhancement

- - Step Load Test: 1.5 tons (50% above EN 13101) – supports two fully equipped workers simultaneously

- - Safety Cage: GB 50303 fall-protection certified – reduces shaft fall accidents by 95%

2. Lifecycle Economics

- - 30-Year Cost Analysis:

- - Steel ladders: 4 replacements

- - Ductile Cast Iron ladder: Single installation 56% cost saving

3. Special Scenario Adaptability

- - Chemical Sewage Shafts: PTFE coating resists strong acids (pH 1–2) – 10-year zero-corrosion case in Ningbo Petrochemical Zone

- - Coastal Deep Shafts: 316L stainless steel fittings + Zn-Ni alloy coating – withstands >10,000 ppm chlorides

III. Typical Applications

- Utility Tunnels:

Shanghai Expo Park (8m depth, 80% faster installation)

- Hazardous Environments:

Wastewater treatment sedimentation tanks (H₂S corrosion resistance + gas monitoring)

Chemical plant pipe shafts (acid/alkali-resistant version, pH 1–14 tolerance)

- Smart Cities:

Shenzhen Qianhai Project (vibration sensors + AI safety alerts)

IV. Standards & Certifications

- International:

EN 1433 (Ladder load class) | ISO 1461 (Hot-dip galvanizing)

- China:

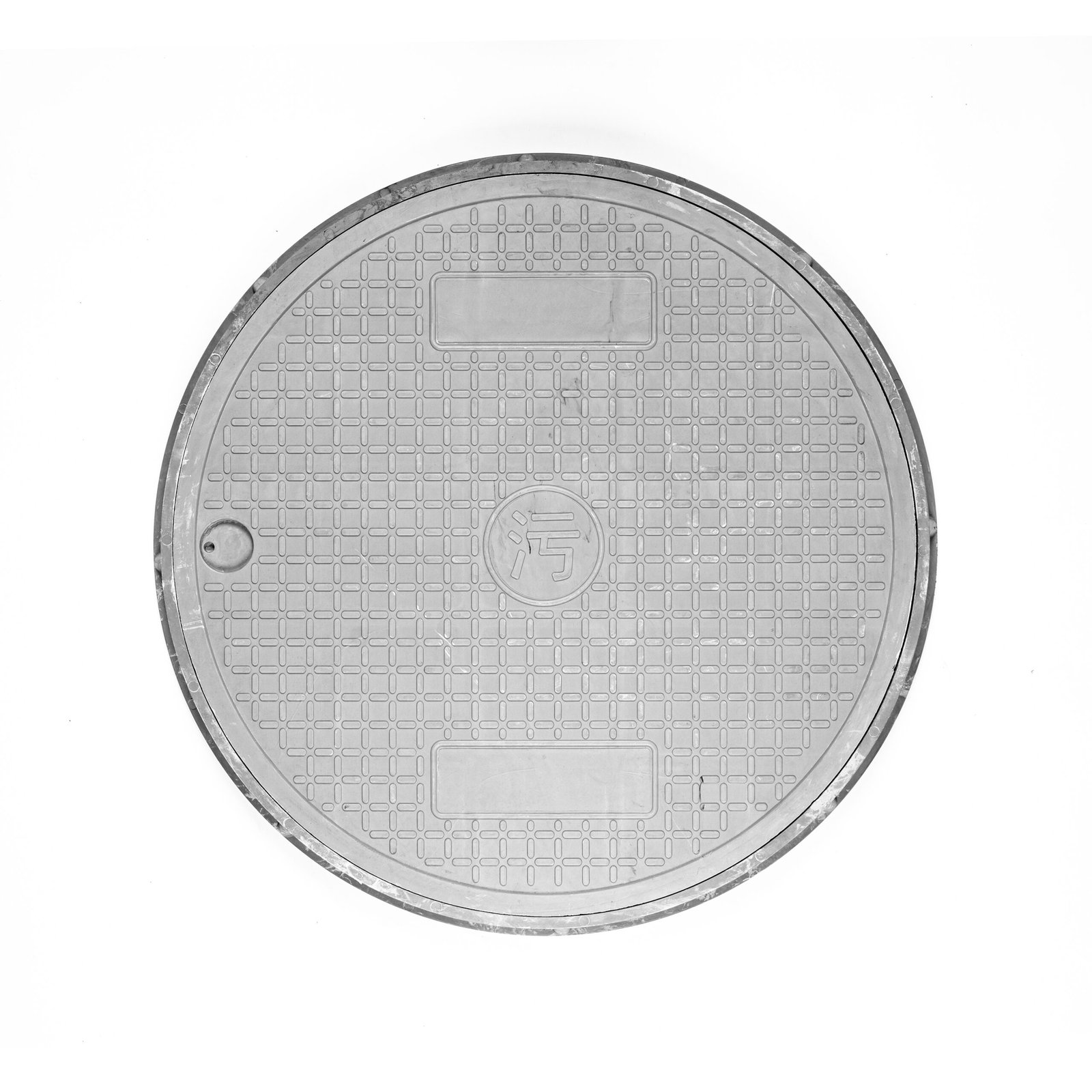

GB 50303 (Electrical construction safety) | GB/T 23858-2009 (Manhole cover systems)

- Special Certifications:

SGS salt spray test >3,000 hrs report | EU CE (CPR 305/2011)

Conclusion

Ductile Cast Iron Ladders redefine shaft safety standards through military-grade strength, lifetime corrosion resistance, and rapid installation:

1. Safety Revolution: Diamond-pattern treads + safety hooks achieve "zero falls" target.

2. Economic Dominance: 30-year maintenance-free lifespan – total cost = 40% of steel ladders.

3. Smart Capabilities: Vibration/gas monitoring eliminates accidents at their source.

Engineering Recommendations:

- Deep shafts (>5m): Strongly recommend safety hook systems

- Chemical zones: 316L stainless steel fittings as standard

- Smart utility tunnels: Integrate LoRa safety monitoring modules