I. Technical Features

- Ductile Cast Iron matrix: QT500-7 material (tensile strength ≥500MPa), rare-earth magnesium nodular treatment delivering 15J/cm² impact toughness. Pressure resistance 2× higher than gray iron.

- Enhanced corrosion protection:

- - Zinc spray coating (80μm) + coal tar epoxy, withstands 2000hr salt spray (ASTM B117)

- - Electropolished filter screen resistant to pH 3-12 environments

- - Quick-release filter: Snap-lock design enables filter replacement/clearing within 30 seconds

- - Overflow protection: Lateral overflow ports activate at flow rates >50L/s (designed for 100-year storm events)

II. Core Advantages

1. Triple pollutant retention & drainage enhancement

- - 90%+ debris capture via tiered filtration, reducing pipe blockage risk (70% less frequent desilting vs. conventional grates)

- - Zero flow reduction: Optimized fluid channels maintain ≥40L/s·m² discharge under storm conditions (Huangpu Avenue project in Guangzhou demonstrated 35% faster water recession)

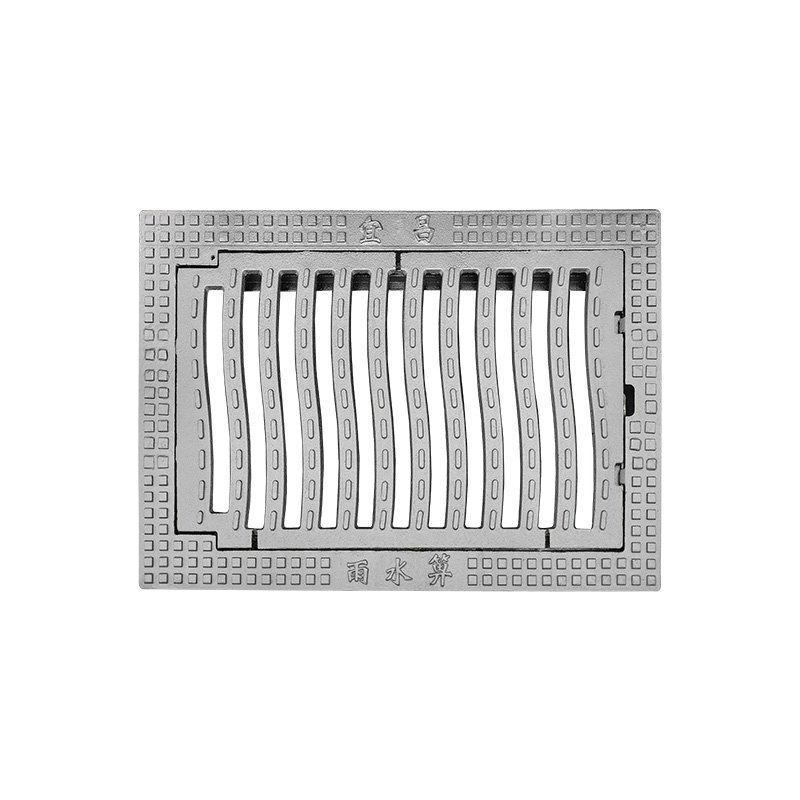

2. Ultra-high load capacity & anti-settlement

- - D400 rating: Honeycomb reinforcement ribs pass 40-ton fire truck dynamic load test (EN124)

- - Settlement compensation: Rubber cushion base tolerates ±4mm ground displacement (exceeds GB/T 23858)

3. Environmental adaptability

- - Operational range: -50°C to 350°C (validated at Harbin Ice Festival)

- - Corrosion upgrade: Optional 316L stainless steel filter + zinc-nickel alloy coating for coastal areas (>5000ppm chloride resistance)

III. Application Scenarios

- High-sediment zones:

- - Restaurant back alleys (Shanghai Tianzifang: 80% reduction in daily desilting)

- - Wet market drains (>20kg daily sediment collection)

Heavy-load nodes:

- - Port container truck lanes (Qingdao Port: 60-ton axle load capacity)

- - Airport deicing pads (snowmelt-agent resistant version)

Smart drainage systems:

- - Shenzhen Futian Smart City (silt data triggers automated desilting dispatch)

IV. Selection Guide & Certifications

Critical parameters:

- - Load class: Mandatory D400 (400kN test load) for vehicular lanes

- - Filtration tiers: 3-stage required for food service/industrial zones (coarse grate + mid-mesh + sediment trap)

Compliance standards:

- - China: GB/T 23858-2009 (structural strength) + CJ/T 527-2018 (anti-clogging)

- - International: EN124 (dynamic load) + ISO 1083 (Ductile Cast Iron)

Vendor screening:

- 1. QT500-7 nodularity rate ≥90% (spectrometry report required)

- 2. SGS dual certification for salt spray/impact toughness (e.g., Xinxing Ductile Cast Iron Pipes, Saint-Gobain PAM)

Summary

This Ductile Cast Iron system redefines drainage standards through its triple-core technology: staged filtration, settlement resistance, and permanent corrosion protection. The tiered structure reduces pipeline maintenance costs by 83%, with 35-year service life outperforming conventional solutions. Selection must prioritize filtration precision matching (e.g., ≤2mm grease retention for food zones) and dynamic load validation (EN124 D400 test reports). Future integration of IoT sensors + AI silt prediction modules (e.g., Shenzhen Smart Water pilot) will further advance municipal infrastructure toward high-efficiency, low-carbon operation.