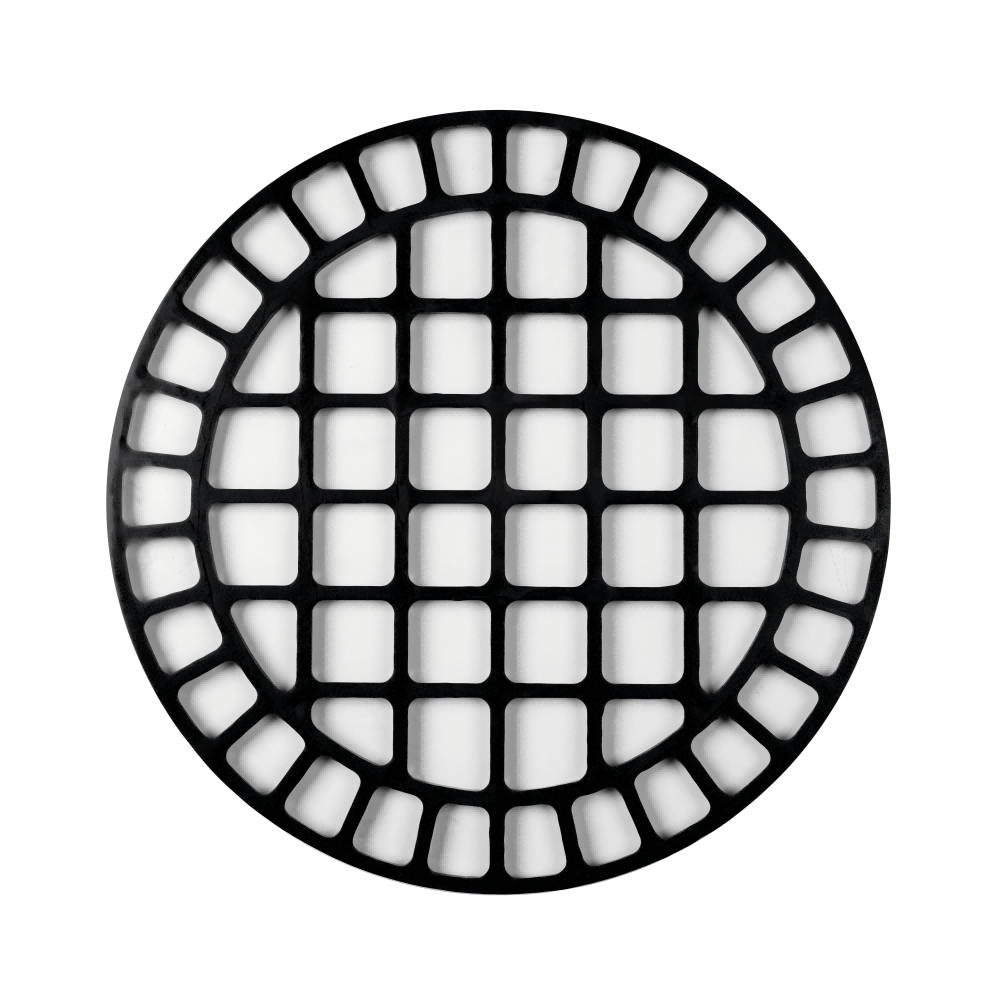

The ductile iron overflow manhole cover is a specialized cover designed for urban drainage systems, crafted from QT500-7 ductile iron. It features controlled overflow functionality to redirect excess stormwater to designated areas (e.g., retention basins or natural water bodies) during heavy rainfall or extreme flow events, preventing urban flooding. Its core functions include dynamic flow control, high-impact drainage, and system overload protection, making it suitable for both combined and separated drainage systems.

With exceptional drainage capacity, extreme durability, and smart scalability, this cover serves as a critical component in modern urban flood prevention systems. Its technical maturity has been validated in flood control projects in cities like Wuhan and Zhuhai. Future integration with digital twin technology (e.g., real-time hydrological modeling) will further enhance urban emergency response capabilities. Selection should prioritize overflow efficiency, load-bearing performance, and anti-corrosion processes to ensure reliability in extreme scenarios like storms and floods, safeguarding urban resilience.