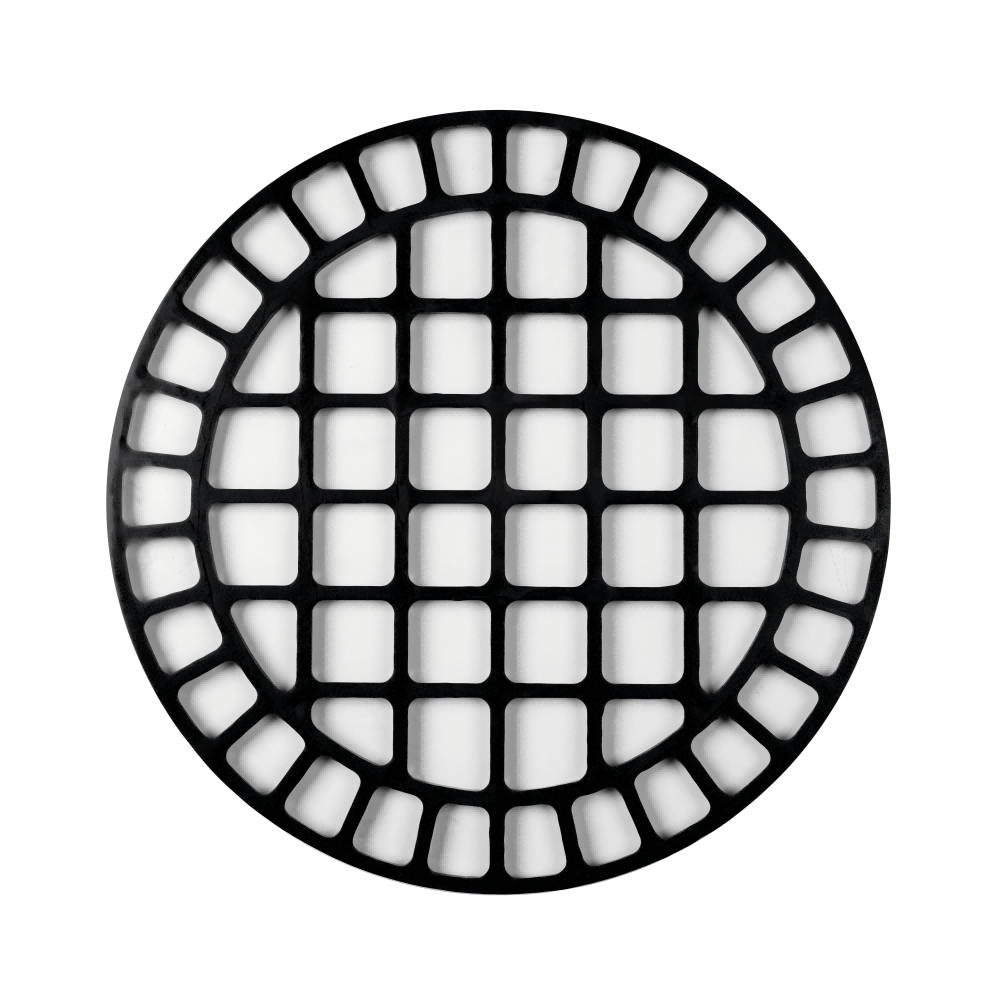

The ductile iron single grate (trench cover) is a linear drainage cover device cast from QT500-7 ductile iron, specifically designed for linear drainage scenarios such as road gutters and plaza drainage channels. Its core functions include high-efficiency drainage through dense grate slots, load-bearing capacity, debris interception, theft resistance, and durability, making it ideal for medium-to-high traffic areas.

By integrating high strength, modularity, and corrosion resistance, this grate serves as a critical component in modern linear drainage systems. Its technical maturity has been validated in municipal projects nationwide. Future integration with smart monitoring modules (e.g., flow sensors) will upgrade it into a smart drainage node. Selection should prioritize load rating, anti-corrosion processes, and splicing compatibility to ensure stable performance in extreme weather and high-load scenarios, safeguarding urban safety and ecological resilience.