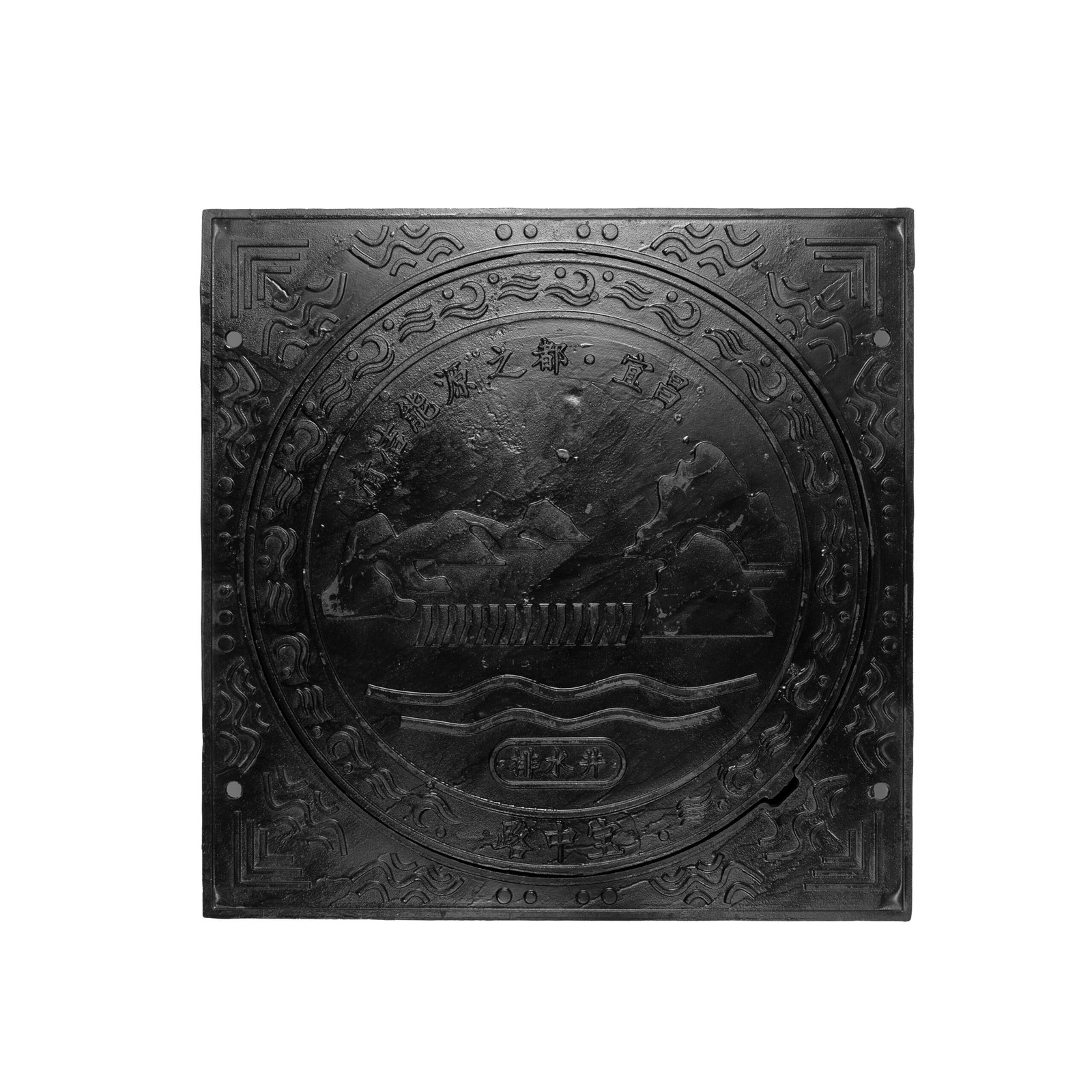

This hybrid masterpiece merges mechanical elegance with engineering philosophy—a square frame tames ground deformation while a circular cover disperses crushing loads. Its 120mm-thick ductile iron body bears not just vehicles, but urban safety itself; 50-year corrosion resistance pledges sustainable legacy. When floods strike, its liquid sensors outpace rescue teams; when tampered with, its tilt alerts scream to city centers—transcending a mere cover to become an intelligent guardian of urban lifelines.

700×800×120 Ductile Iron Square-Frame Circular Cover

-

Product Features:

Hybrid Structure Advantage,Heavy-Duty Load Capacity,Zero-Maintenance Economy

-

Inquire Now

- hubeiluzhongbao@gmail.com

-

Product Description

I. Structural Ingenuity

1. Square-Circle Hybrid Design

- Square Frame (700×800mm): Embeds perfectly into asphalt/concrete cutouts, eliminating rotational displacement.

- Circular Lid (Ø650mm): Converts traffic loads into radial stress (35% higher crush resistance than rectangular covers).

2. Three-Tier Anti-Settlement System

- Flange Load Dispersion: 150mm-wide flange transfers 80% pressure to road base.

- Elastic Buffer: Neoprene pad compensates for subgrade shifts.

- Self-Leveling Frame: Wedge bolts (±15mm adjustment) ensure perpetual flatness.

3. Fivefold Safety Interlock

- Anti-Theft: Triple hidden-mortise locks require torque-specific tools.

- Anti-Fall: 30×30mm ductile iron grating (300kg capacity).

- Anti-Shift: Eight M20 anchors (500mm deep).

- Anti-Noise: U-groove silicone seals cut 18dB vibration noise.

- Anti-Slip: Diamond knurls (0.92 friction coefficient).

II. Five Battlefield Advantages

1. Double Settlement Resistance

- Frame-asphalt fusion limits settlement to ≤2mm after 5 years (vs. >10mm for conventional covers).

- Sealed apron blocks rain-induced "frame rot."

2. 50-Ton Load Mastery

120mm thickness + cruciform ribs withstand 50 tons (exceeds GB/T 23858 D400). Zero deformation under daily garbage compactor loads.

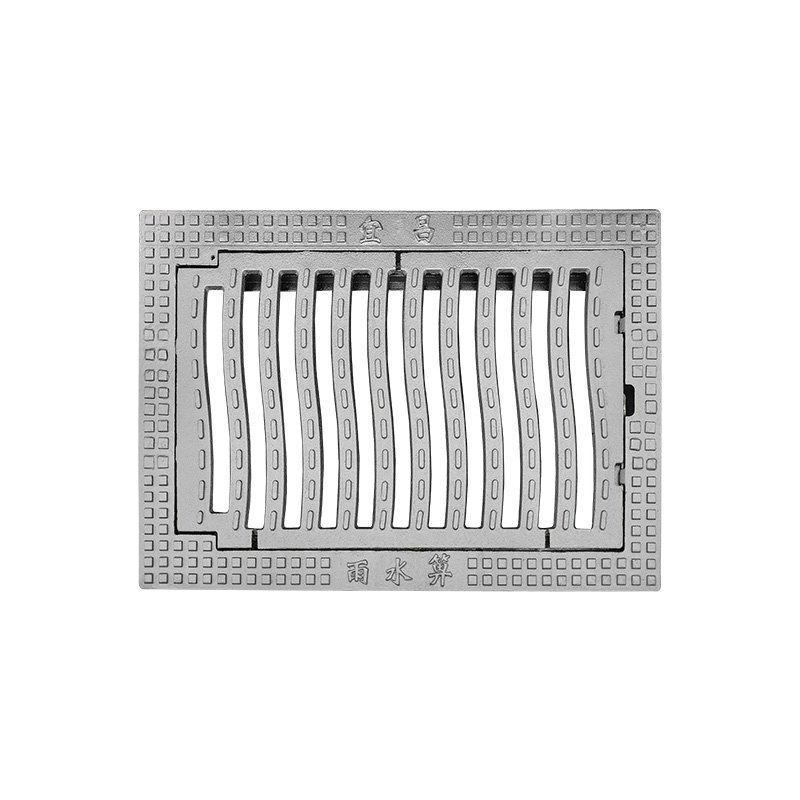

3. Drainage & Access Excellence

- Circular Lid: 30% faster drainage than square covers; debris slides along curvature.

- Square Frame: Pry-bar grooves enable manual lifting (75kg total—35% lighter than solid squares).

4. -40°C to 150°C Resilience

- Thermal-sprayed aluminum + epoxy-polyurethane coating survives deicers/oil/acid for 30+ years.

- Zero thermal deformation from permafrost to paving heat.

III. Master Installation Protocol

1. Flange-Road Fusion

- Excavate >100×90cm; set frame 3cm below surface.

- Embed during 140°C asphalt lay; compact at 110°C with crosshatch rolling.

2. Anchor Anti-Shift Technique

- Install M20 bolts at 15° outward angles (≥35cm depth) in steel-fiber C30 concrete.

- Trim excess bolts; seal with hot asphalt.

- 3. Drainage Slope Duo

- 3° outward frame tilt directs water to central lid.

- ≥5% base slope + center cone accelerates flow.

IV. Unrivaled Applications

- 1. Narrow Mixed-Use Lanes: Square frame aligns with curbs; circle prevents puddles.

- 2. Bus Stops: Slip-proof + silent for passenger safety.

- 3. Old Community Entrances: Fits 5m hybrid roads perfectly.

- 4. Landscaped Walkways: Rounded edges blend with stonework.

- 5. Chemical Plant Paths: Acid-proof coating + fall protection for inspectors.

Vs. Pure Circle/Square Covers: 15% stronger than squares, 30% better drainage than circles, with pinpoint alignment—the ultimate hybrid for complex zones!

Epilogue: Square and Circle, Resilience and Rigidity

Two decades in the field, I’ve seen circular covers spin under pressure and square ones drown in storms. The 700×800×120 hybrid thrives in tight spaces by taming settlement with its square frame, channeling floods with its circular core, and embodying 50-year resilience. Next time you wait at a bus stop, notice that iron square embracing the moon—silently harmonizing wheels and footsteps, storms and sun, guarding the flowing order and warmth of the city within its bounds.

Luzhongbao

High Precision from Luzhongbao!

Provide your needs

Request a Quote

If you have any questions

please feel free to contact us.

Focus on the field of caterpillar mobile crushing and screening, so that solid waste recycling more efficient!