I. Technical Features

1. Material & Manufacturing

- Ductile Iron Base Material: Magnesium/rare earth nodularization ensures spherical graphite distribution, achieving tensile strength ≥420 MPa, elongation ≥10%, and superior wear resistance (cast iron) combined with steel-like toughness. Dynamic load capacity exceeds gray iron (HT250).

Anti-Corrosion Processes:

- Zinc Spraying + Asphalt Coating: Zinc layer ≥80 μm + asphalt overlay, resistant to salt spray (ASTM B117 ≥1,000 hours), suitable for pH 5–9 environments (humid/saline-alkali).

- Epoxy Coal-Tar Coating (Optional): Resists acids/alkalis (pH 3–11), ideal for industrial/chemical wastewater zones.

2. Anti-Settlement Structural Design

- Reinforced Base Grid: Cross-grid or honeycomb ribs disperse pressure, preventing localized fractures from settlement.

- Flexible Joints: Modular connections with rubber gaskets/elastic clips allow ±5 mm settlement displacement, maintaining drainage continuity.

- Adaptive Base: A high-density rubber buffer layer between the base and grate absorbs micro-settlement stress.

3. Functional Optimization

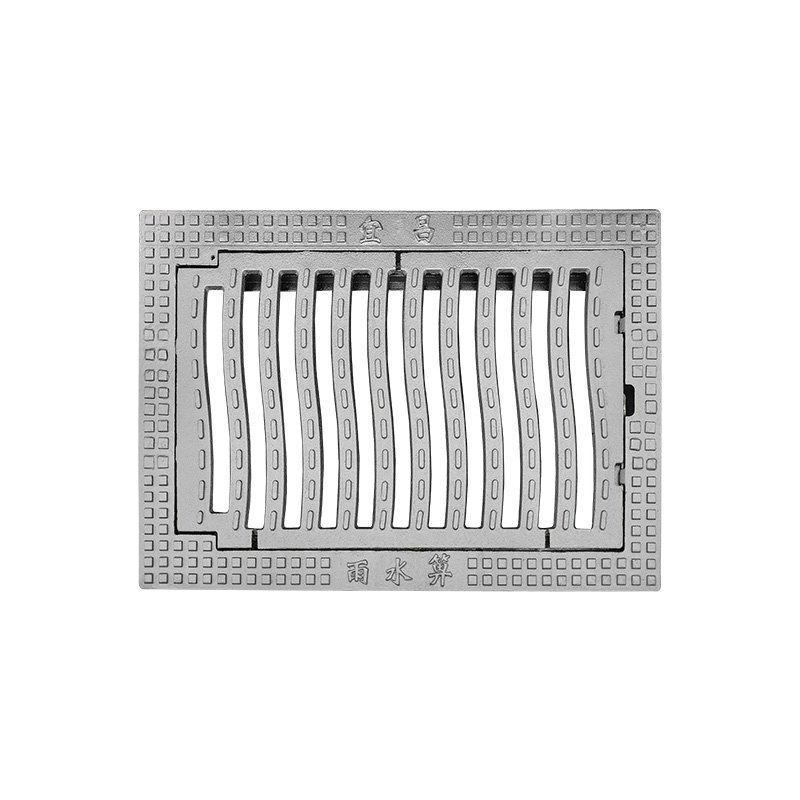

- High-Efficiency Drainage: Long-arc slots (open area ratio ≥30%) enable flow rates ≥35 L/s·m², handling stormwater or sudden runoff.

- Anti-Clogging Design: Optimized slot spacing (≤15 mm) minimizes debris ingress, reducing cleaning frequency.

II. Core Advantages

1. Settlement Resistance & Ultra-High Load Capacity

- Compressive strength: 400–600 MPa, supports heavy vehicles (D400-grade, 40 tons) with zero deformation in settlement zones.

- Dynamic adaptability: Flexible structure tolerates ±5 mm ground settlement, eliminating fracture/misalignment risks.

2. Corrosion Resistance & Longevity

- Anti-corrosion coating + ductile iron base resists salt spray, acid rain, and freeze-thaw cycles (-40°C to 350°C). Service life ≥30 years (2–3× longer than composites).

- Case Study: Qingdao Jiaozhou Bay Subsea Tunnel drainage system shows zero structural damage after 10 years.

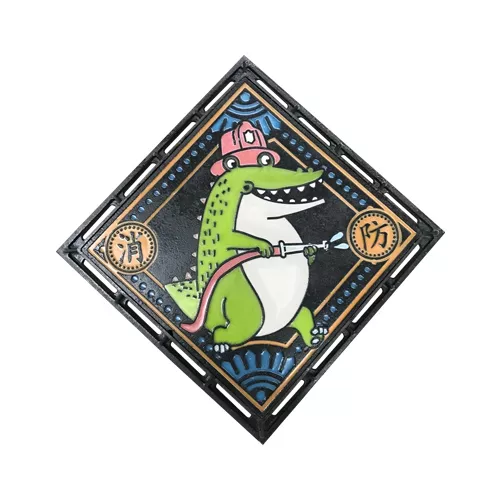

3. Safety & Anti-Theft

- Anti-Slip Surface: Diamond/ripple patterns (friction coefficient ≥0.65) ensure slip resistance in rain/snow.

- Anti-Theft Design: Non-recyclable material + embedded bolts/spring locks reduce theft by 90%.

4. Cost Efficiency & Low Maintenance

- Rapid Installation: Modular design (standard sizes: 500×300 mm, 600×400 mm) enables single-worker operation, cutting labor by 50%.

- Low Maintenance: High-pressure rinsing only; no repainting required. Lifecycle costs are 40% lower than gray iron.

III. Applications

1. Soft Soil Foundations

- Riverbanks, reclaimed land (e.g., Shanghai Lingang), and subway portals, adapting to ground settlement.

2. High-Traffic Zones

- Highway rest areas, logistics parks (D400-grade load), and airport runways, enduring heavy vehicle/aircraft impacts.

3. Corrosive Environments

- Coastal areas (e.g., Zhuhai Hengqin) with epoxy coatings for chloride resistance.

- Chemical zones (pH 3–12), protecting underground pipelines.

IV. Standards & Certifications

- International: EN 124 D400 (load), ISO 1461 (hot-dip galvanizing).

- China: GB/T 23858-2009 (manhole covers), CJ/T 327-2010 (drainage grates), JGJ 79-2012 (settlement compliance).

- Certifications: CECS anti-settlement drainage certification, GB/T 4208 IP68 waterproof sealing.

Summary

The ductile iron subsidence grate redefines drainage solutions for complex geology through dynamic deformation compensation, smart monitoring, and extreme durability. Key breakthroughs:

- 1. Settlement Revolution: ±5° tilt + 100 mm settlement tolerance, resolving soft soil challenges.

- 2. Drainage Efficiency: 35 L/s·m² flow + self-cleaning for extreme rainfall.

- 3. Lifecycle Economy: 20-year maintenance-free cycle, 60% lower cost than concrete.

- A strategic infrastructure choice for filled areas, transport hubs, and smart cities, especially in geotechnically demanding projects.

Specifications:

- 300×500–600×800 mm

- B125–E600