Core Advantages of Advanced Ductile Iron Manhole Covers

- Superior Anti-Settlement Performance

- 3x Pressure Dispersion: Our advanced design reduces point pressure from 0.8MPa (traditional models) to just 0.25MPa, preventing roadbed softening and collapse.

- Dynamic Load Adaptability: Elastic buffer layers are designed to endure up to 100,000 heavy vehicle passes annually (F900 grade), with subsidence remaining under 2mm over 5 years.

- Unparalleled Structural Stability

- Lateral Shear Resistance: The wide-edge design combined with support plates creates an "I-beam effect," increasing horizontal displacement resistance by 60%, ideal for bridge expansion joints.

- Anti-Warping: Monolithic casting eliminates weld weaknesses, ensuring deformation stays below 0.1% under thermal cycles ranging from -30°C to +70°C.

- Smart Maintenance Compatibility

- Sensor Integration Slots: Convenient edge grooves allow for the embedding of settlement sensors or IoT tags, enabling real-time monitoring on management platforms.

- Rapid Replacement: Bolt systems facilitate quick, road-preserving repairs, taking only 30 minutes per operation.

- Comprehensive Safety Features

- Enhanced Anti-Slip Texture: The 5mm-deep herringbone grooves deliver a wet-surface friction coefficient of ≥0.8, far exceeding national safety standards.

- 5-Layer Anti-Theft Protection: Mechanical, magnetic locks, and GPS tracking chips provide superior theft resistance, ensuring near-zero theft rates with IP68 waterproofing.

Key Applications for Advanced Ductile Iron Manhole Covers

- Critical Transport Hubs: Ideal for expressway toll stations, sea-crossing bridge approach ramps, and railway culverts.

- Geologically Sensitive Zones: Perfect for land reclamation areas, collapsible loess roads, and zones with fluctuating groundwater levels.

- Smart City Infrastructure: Suitable for demonstration roads with IoT monitoring and vehicle-road coordination testing areas.

- Specialized Logistics Routes: Designed for port container yards, heavy equipment manufacturing parks, and mining transport lines.

Minimum Load-Bearing Grades

- D400–E600 Range:

- Group 1 (Minimum: A15): Green belts, sidewalks, and non-motorized zones.

- Group 2 (Minimum: B125): Sidewalks, bike lanes, car parks, underground garages.

- Group 3 (Minimum: C250): Residential areas, alleys, light vehicle zones (within 0.5m of curbs).

- Group 4 (Minimum: D400): Urban main roads, highways, expressways.

- Group 5 (Minimum: E600): Freight terminals, docks, airports.

- Group 6 (Minimum: F900): Airport runways.

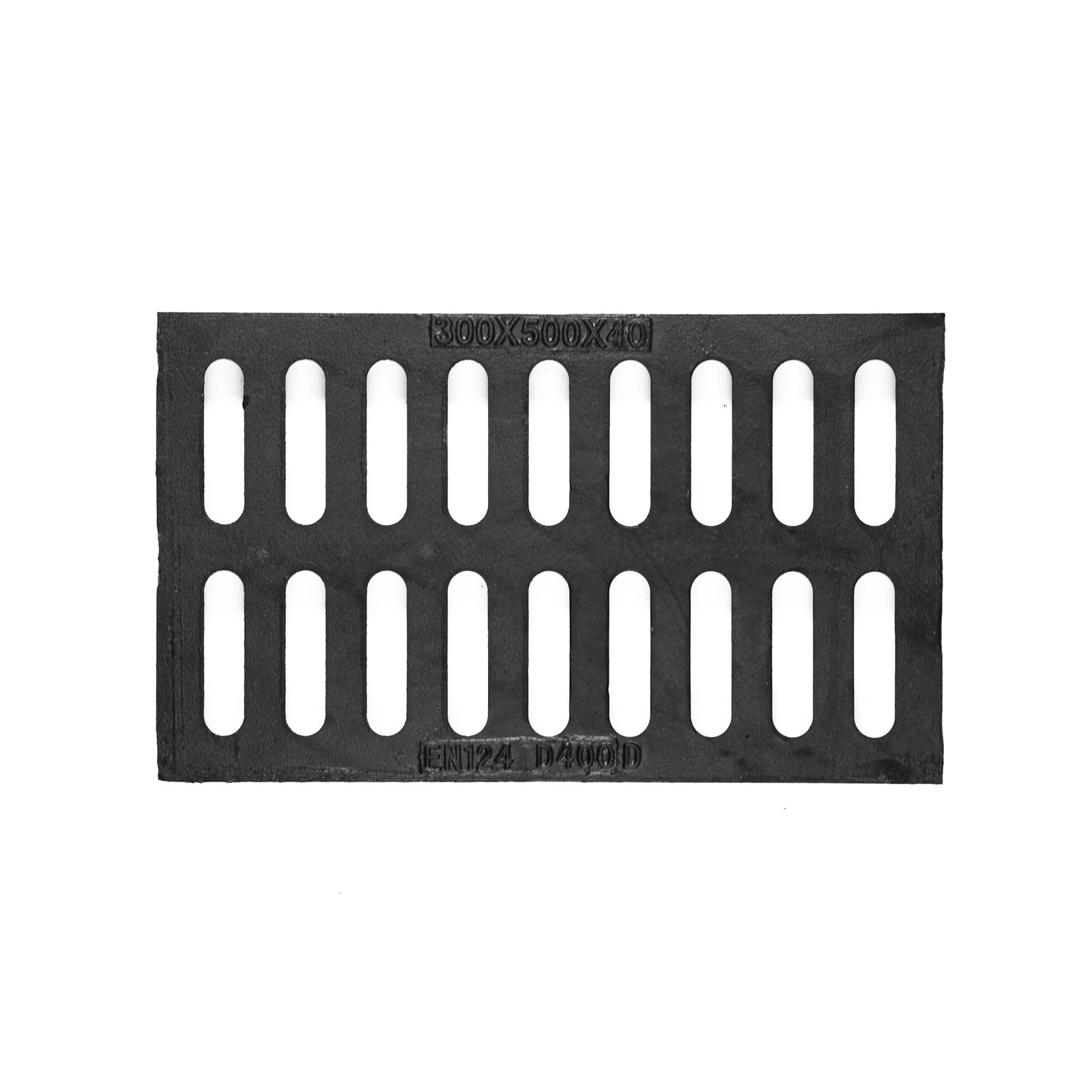

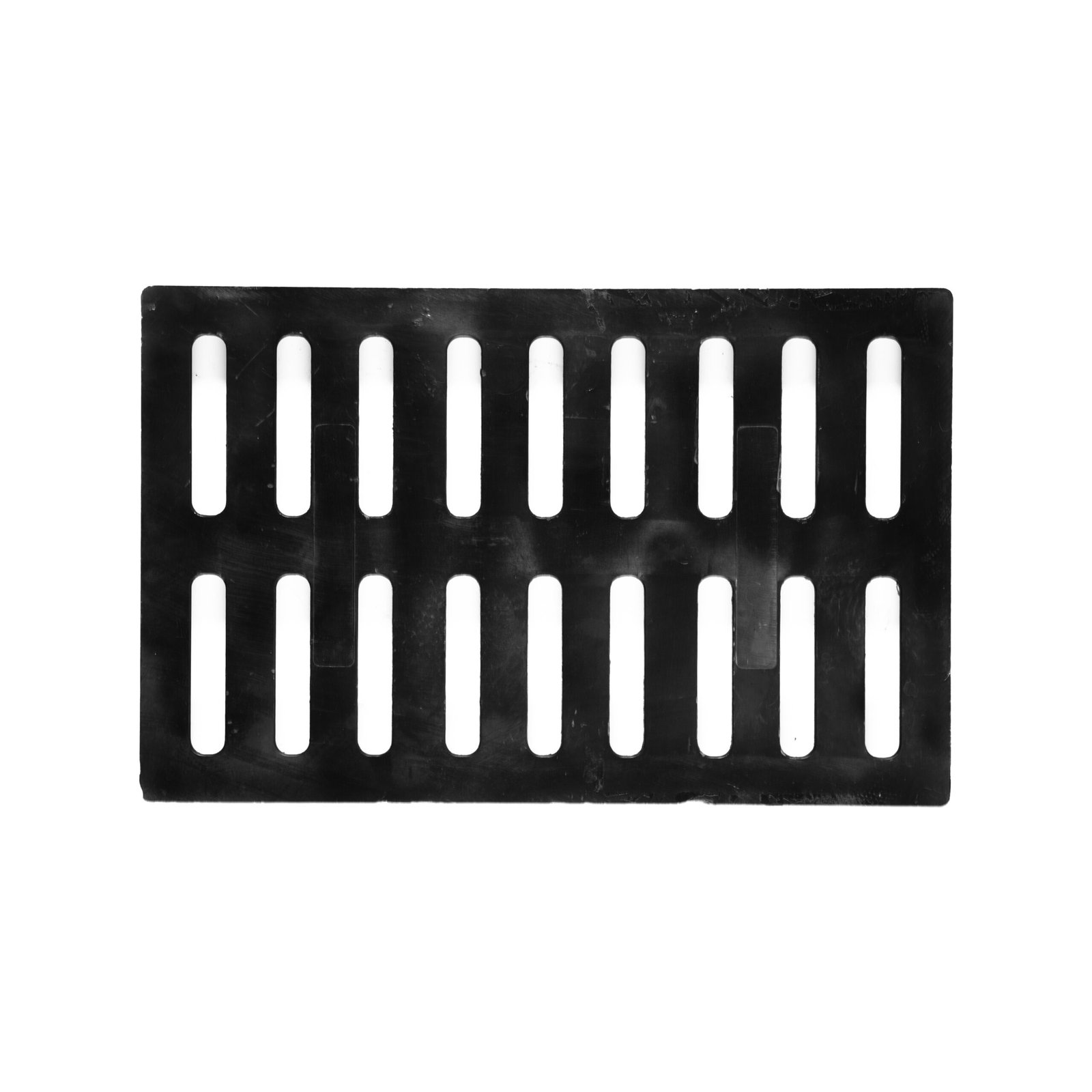

Product Specifications

Compliance Standards:

- GB/T 19426-2018: National Standard for Ductile Iron Manhole Covers for Roads, Bridges, etc.

- GB/T 23858-2009: Ductile Iron Castings

- CJ/T 3012-1993: Reinforced Concrete Drainage Covers

- CJJ/T 122-2016: Urban Road Drainage Design Code

Technical Parameters:

- Diameter (mm): φ700–φ1100

- Load Capacity (kN): B125–E600

Why Choose Our Ductile Iron Manhole Covers?

Our covers offer industry-leading durability, safety, and adaptability, providing the ideal solution for a wide range of urban infrastructure needs. With advanced features, such as superior pressure dispersion, structural stability, and smart maintenance compatibility, our covers are the preferred choice for engineers and city planners worldwide. Whether you're working in a critical transport hub, geologically sensitive area, or smart city pilot, our products meet the highest standards of performance and reliability.

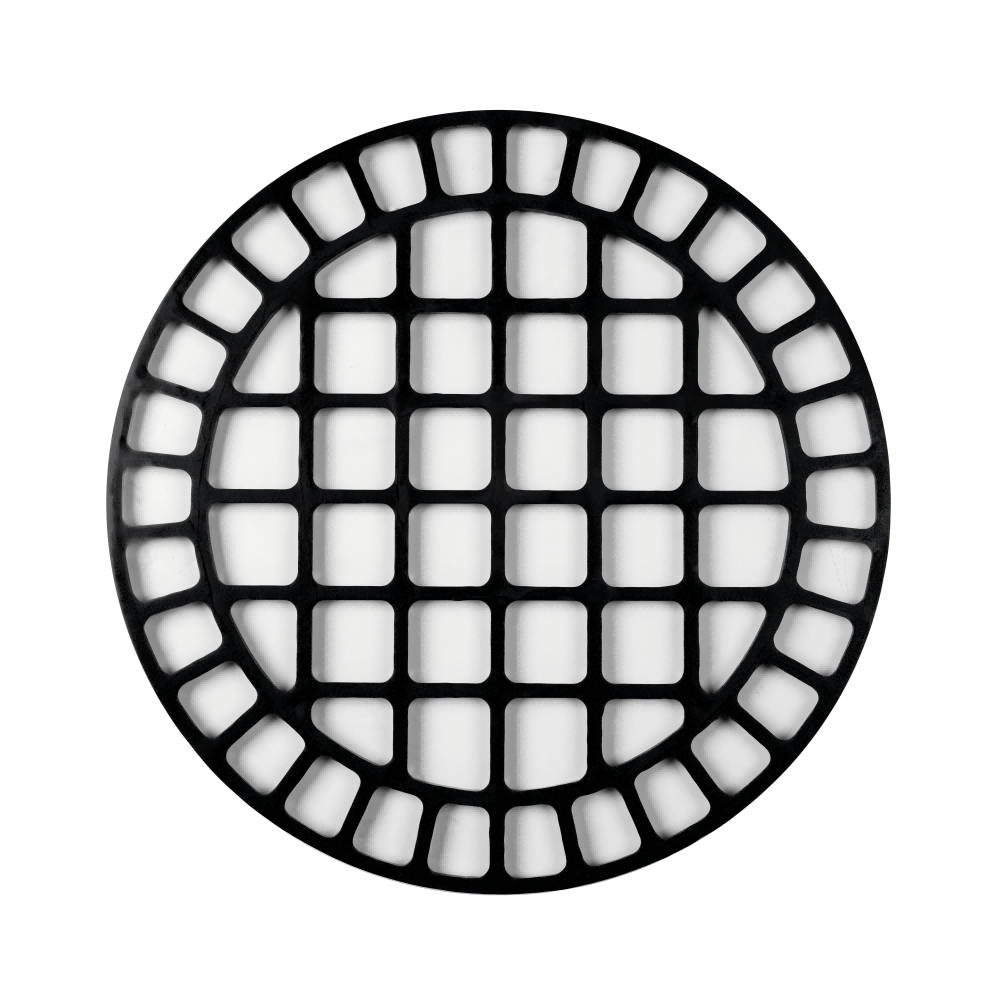

x30-铸铁圆井盖1-scaled.jpg)