Against the backdrop of increasing complexity in modern urban underground pipeline networks, traditional symmetrical inspection chambers often struggle to meet spatial adaptability requirements in specific working conditions. Especially in special spatial environments such as pipeline transition nodes, road widening areas, and around existing structures, it is necessary to ensure the structural integrity of the inspection chamber while also adapting to non-standardized spatial layout needs. The Luzhongbao 700×370×60 Composite Rectangular Chamber is developed specifically for working conditions with special spatial constraints, based on asymmetric structural mechanics analysis and spatial optimization design. Through the rectangular combination of a 700mm long side and a 370mm short side, this product achieves precise adaptation to elongated areas while ensuring sufficient operating space, providing an innovative solution for underground pipeline network construction under special conditions.

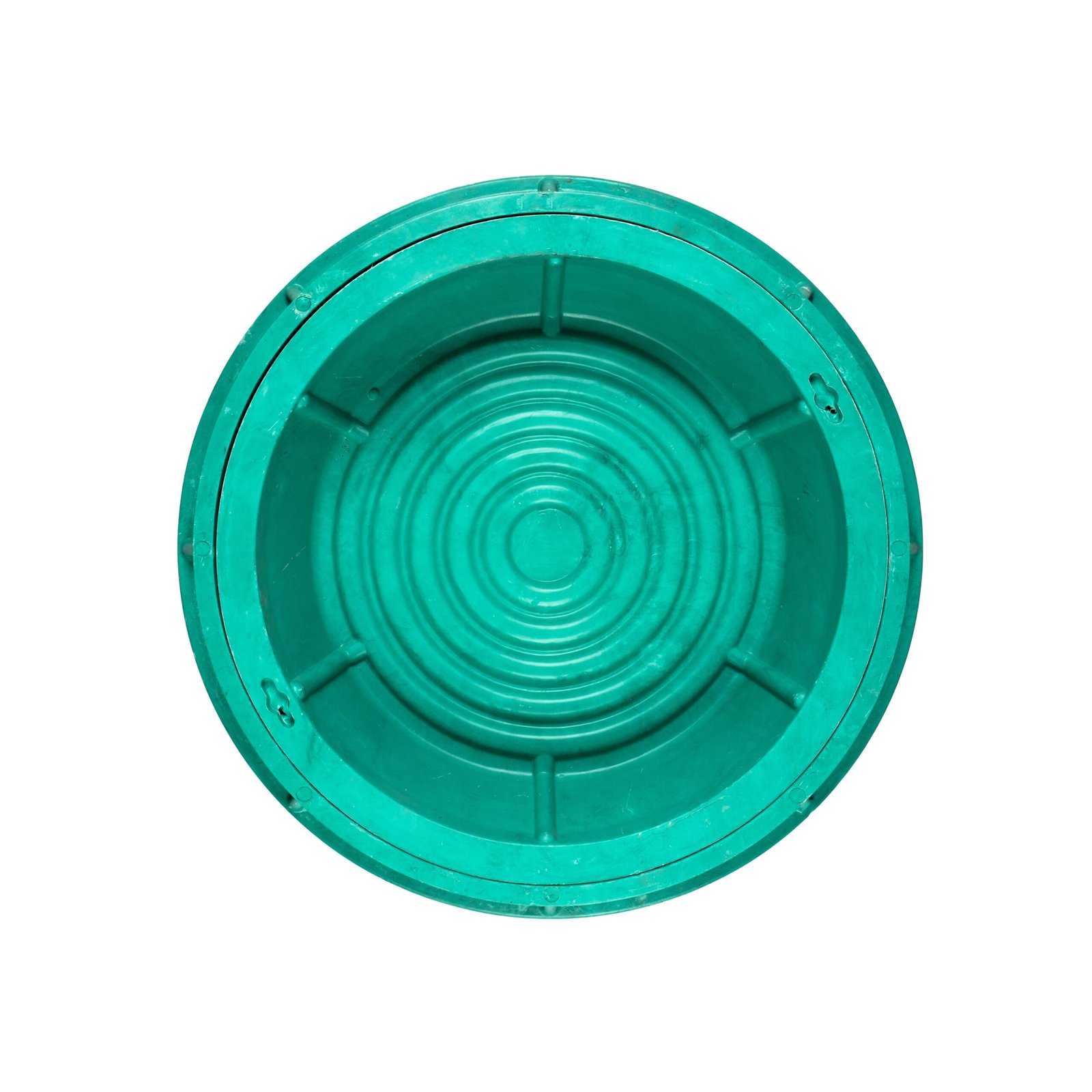

Luzhongbao 700×370×60 Composite Square Manhole Cover

-

Product Features:

Anti-Theft Design,Lightweight & High Strength,Corrosion & Rust Resistant

-

Inquire Now

- hubeiluzhongbao@gmail.com

-

Product Description

Luzhongbao 700×370×60 Composite Square Manhole Cover: A High-Performance Engineering Solution under Asymmetric Structure.

This product adopts a high-performance composite material system. Its external dimensions are 700mm (length) × 370mm (width) × 60mm (wall thickness). This meticulously calculated asymmetric design ensures ample internal operating space while minimizing underground space occupation to the greatest extent. The 60mm thickened wall incorporates a differentiated reinforcement structure design: primary load-bearing ribs are set along the long side direction, supplemented by a stability support network along the short side direction, effectively balancing stress distribution under the asymmetric structure. The product inherits the excellent characteristics of composite materials: corrosion resistance, insulation, and no scrap value. Its smooth internal surface and standardized interface system ensure smooth pipeline connections. A specially designed non-slip step system provides safe working conditions for maintenance personnel. The overall structural design life exceeds 30 years, capable of meeting long-term use requirements under various complex geological conditions.

Material System and Manufacturing Process

The structural reliability of this rectangular chamber stems from its advanced material formulation and manufacturing technology. The matrix material uses high-strength vinyl ester resin. By adding flexible chain segment modifiers, the material maintains rigidity while possessing excellent impact toughness. The reinforcement system adopts a composite structure of warp-knitted bidirectional glass fiber fabric and chopped fibers, achieving focused reinforcement along the long side direction through differentiated ply design.

The manufacturing process utilizes a 10,000-ton hydraulic press for compression molding. A unique temperature curve control system ensures the material completes the curing reaction under optimal conditions. The mold design employs patented asymmetric cooling technology, effectively resolving internal stress issues during the molding of large asymmetric products. The finishing process uses five-axis CNC machines for precision machining of interface areas, ensuring connection accuracy reaches the industry-leading level of ±0.2mm.

Structural Design and Mechanical Performance

The core technical breakthrough of this product lies in its optimized asymmetric structural design. Within the 60mm wall thickness space, a clearly prioritized primary and secondary reinforcement network is established. The spacing of the longitudinal ribs arranged along the long side direction is precisely calculated, while effective force transfer in the short side direction is achieved through diagonal support ribs. The four corners of the chamber employ a gradually changing arc design, significantly improving the load-bearing capacity in stress concentration areas.

Tested by the National Building Materials Testing Center, the ring stiffness of this rectangular chamber reaches SN15 grade. The bending strength along the long side direction reaches 180 MPa, and the compressive strength along the short side direction reaches 220 MPa, fully meeting the most stringent requirements for urban roads. The interface system uses a three-dimensional sealing design, ensuring excellent sealing performance even under asymmetric loading conditions.

Engineering Applications and Comprehensive Benefits

In practical applications within special spatial conditions, this rectangular chamber demonstrates unique advantages. Its asymmetric structure can flexibly adapt to various complex underground spatial layouts, effectively solving the installation difficulties of traditional symmetrical inspection chambers. The product weight is only 1/7 of a concrete chamber of the same specification, significantly reducing transportation and installation costs, making it particularly suitable for application in existing facility renovation projects.

From a whole-life-cycle cost analysis, the product's design service life exceeding 30 years and near-zero maintenance characteristics result in a comprehensive cost reduction of over 40% compared to traditional products. The lack of scrap value completely eliminates theft, while exceptional corrosion resistance ensures long-term stable operation in harsh environments such as chemical industrial parks and coastal areas.

Summary

The Luzhongbao 700×370×60 Composite Rectangular Chamber successfully solves the technical challenge of installing inspection chambers in special spatial environments through the perfect combination of asymmetric structural innovation and materials science. The product not only possesses excellent mechanical performance and durability but also demonstrates significant advantages in spatial adaptability. The successful development of this product provides a new technical option for underground pipeline network construction in complex urban environments, reflecting the trend of modern municipal engineering towards refinement and customization. Choosing this product means providing reliable technical assurance for infrastructure construction under special working conditions

Luzhongbao

High Precision from Luzhongbao!

Provide your needs

Request a Quote

If you have any questions

please feel free to contact us.

Focus on the field of caterpillar mobile crushing and screening, so that solid waste recycling more efficient!