Against the backdrop of modern expressway construction developing towards intelligence and lightweight, problems associated with traditional inspection well cover plates, such as heavy structure, inconvenient installation, and noise pollution, are becoming increasingly prominent. Especially in high-speed driving areas where road surface flatness must be maintained, the structural performance of the cover plate directly affects driving safety and comfort. The Luzhongbao 730×490×20 Composite High-Speed Cover Plate, based on ultra-thin composite structure technology, achieves the load-bearing capacity of traditional thick cover plates at a mere 20mm thickness through innovative material formulations and honeycomb reinforcement structure design, representing the latest breakthrough in lightweight technology for high-speed traffic facilities.

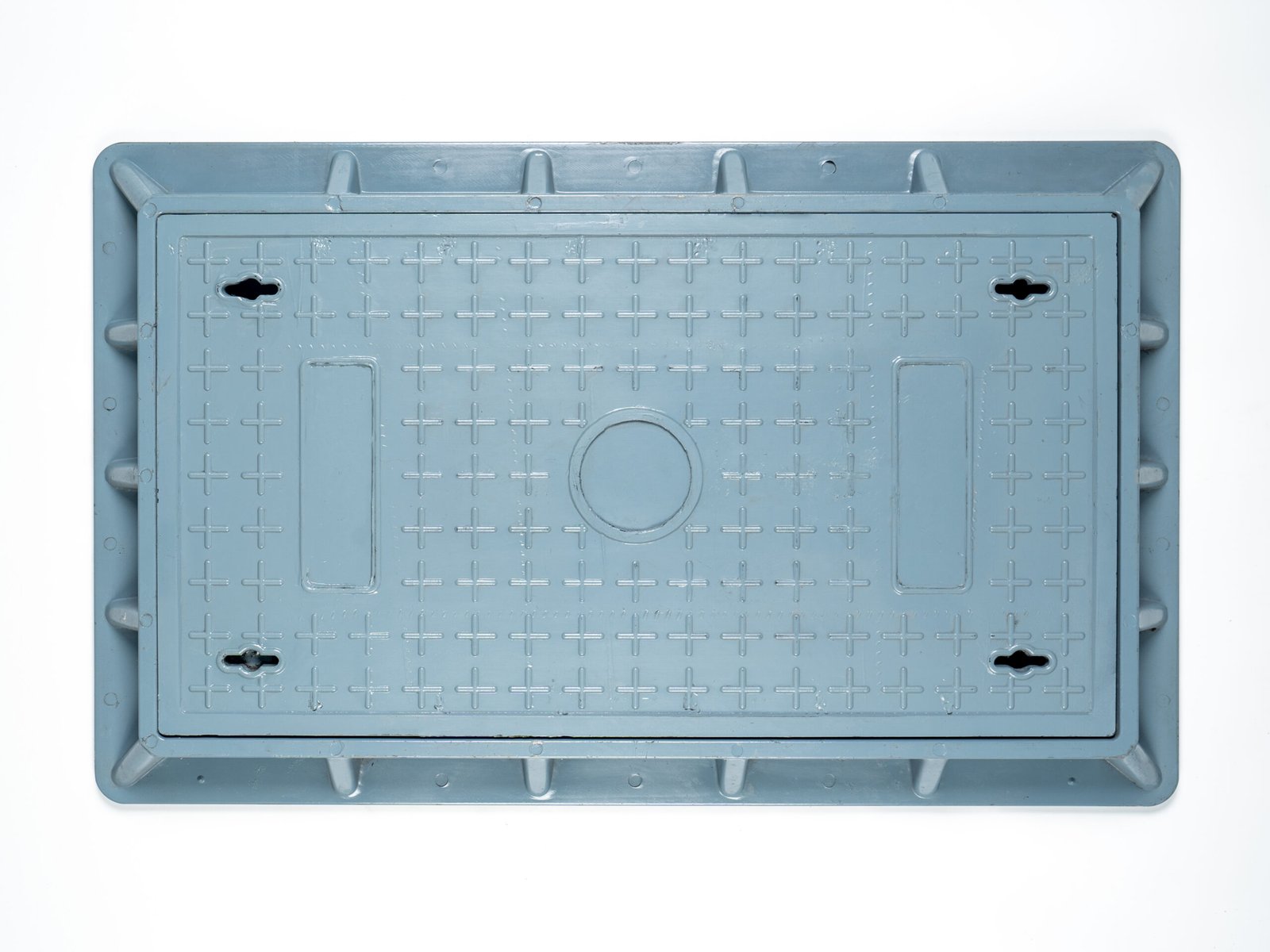

This product adopts an aerospace-grade composite material system. Its external dimensions are 730mm × 490mm × 20mm. This aerodynamically optimized rectangular proportion effectively reduces the wind resistance effect when vehicles pass. The 20mm ultra-thin structure internally uses a bionic honeycomb-like reinforcing grid. Through nano-level fiber directional alignment technology, it achieves the maximum utilization of the material's mechanical properties. The cover plate surface undergoes micron-level anti-skid texture treatment, with a friction coefficient exceeding 0.9, ensuring driving safety in adverse weather conditions like rain and snow. The product's overall weight is only 1/8 of a traditional cast iron cover plate, significantly reducing transportation and installation costs while maintaining excellent fatigue resistance and durability.