I. Technical Features

1. Material & Manufacturing

Material Grades:

- 304 Stainless Steel: General-purpose, corrosion-resistant for urban roads and commercial areas.

- 316/316L Stainless Steel: Molybdenum-enhanced (2–3%), 30% better chloride resistance for coastal/chemical environments.

- Processing: Laser cutting, precision welding, or cold rolling ensures structural accuracy (±0.5 mm tolerance).

- Surface Finishes: Brushed, mirror, sandblasted, or PVD-coated (e.g., titanium) for anti-slip performance (friction coefficient ≥0.6) and aesthetics.

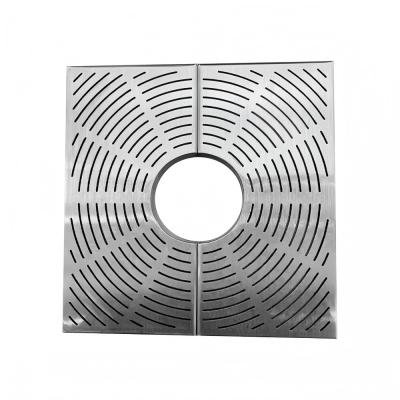

2. Structural Design

- Load Reinforcement: I-beam frames or honeycomb supports enable A15–F900 load ratings (15 kN to 900 kN). EN 1433-certified models (e.g., D400-grade: 40 tons).

- Anti-Displacement: Snap-lock or embedded bolts prevent shifting under vehicle loads.

- Modular Assembly: Standard sizes (600×600 mm, 1000×1000 mm) enable rapid installation in linear drains or cable trenches.

II. Core Advantages

1. Extreme Environment Adaptability

- Corrosion Resistance: 316 withstands pH 1–14 and salt spray (ASTM B117 ≥5,000 hours), outperforming carbon steel/composites.

- Temperature Tolerance: Operational range -50°C to +800°C (short-term), suitable for steel mills/boiler rooms.

2. Ultra-High Strength & Safety

- Compressive Strength: ≥400 MPa, supporting fire trucks/heavy trucks (D400-grade: 40 tons).

- Anti-Drop Design: Grille gaps ≤15 mm (EN 124 compliant) prevent small object loss.

3. Hygiene & Low Maintenance

- Non-Porous Surface: Easy sterilization for HACCP/GMP compliance in food/pharma facilities.

- Cost Efficiency: No rust treatment required; high-pressure rinsing cuts maintenance costs by 70% vs. cast iron.

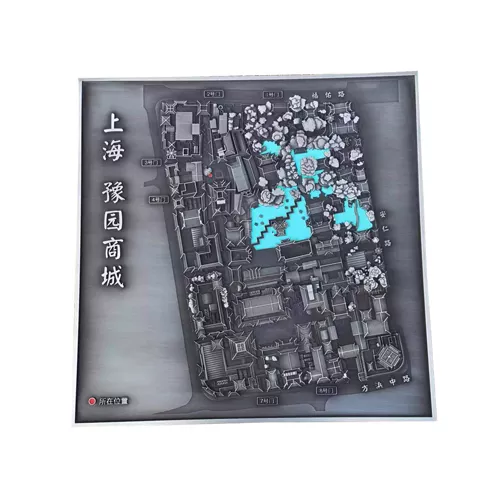

4. Aesthetic Customization

- Landscape Integration: Custom colors (rose gold, champagne), etched logos, or LED-lit designs for luxury plazas.

- Flush Mounting: Seamless alignment with stone/tile pavements.

5. Sustainability & Economy

- 100% Recyclable: 60% lower carbon footprint vs. cast iron; LEED-certified.

- Lifecycle Savings: 30+ year lifespan offsets higher initial costs.

III. Applications

1. Food & Pharma:

- Slaughterhouse drains, dairy plants (grease-resistant, easy-clean).

- Pharma cleanrooms (GMP-compliant).

2. Municipal & Transport:

- Airport/port drainage (salt/fatigue-resistant).

- Subway/high-speed rail access (vibration-resistant).

3. Industrial & Energy:

- Chemical plant acid drains (H₂SO₄/HCl-resistant).

- Nuclear plant/data center ventilation covers.

4. Commercial & Public:

- Urban renewal (theft-resistant alternative to cast iron).

IV. Standards & Certifications

- International: EN 10088-2 (stainless steel), ISO 14122-3 (safety).

- China: GB/T 3280-2015 (stainless sheets), HG/T 20538-2016 (anti-corrosion).

- Certifications: NSF/ANSI 61 (water safety), EHEDG (hygiene).

Summary

Stainless steel trench covers redefine industrial and municipal infrastructure with unmatched corrosion resistance, strength, and smart hygiene. Key strengths:

- 1. Universal Protection: Resists extreme chemicals, temperatures (-50°C to +800°C), and salinity.

- 2. Lifecycle Efficiency: 50-year maintenance-free operation, total costs 40% lower than galvanized steel.

- 3. Digital Integration: IoT compatibility enables smart facility management.

An irreplaceable solution for heavy industry, sterile facilities, and high-traffic zones, particularly where safety, durability, and aesthetics are non-negotiable.

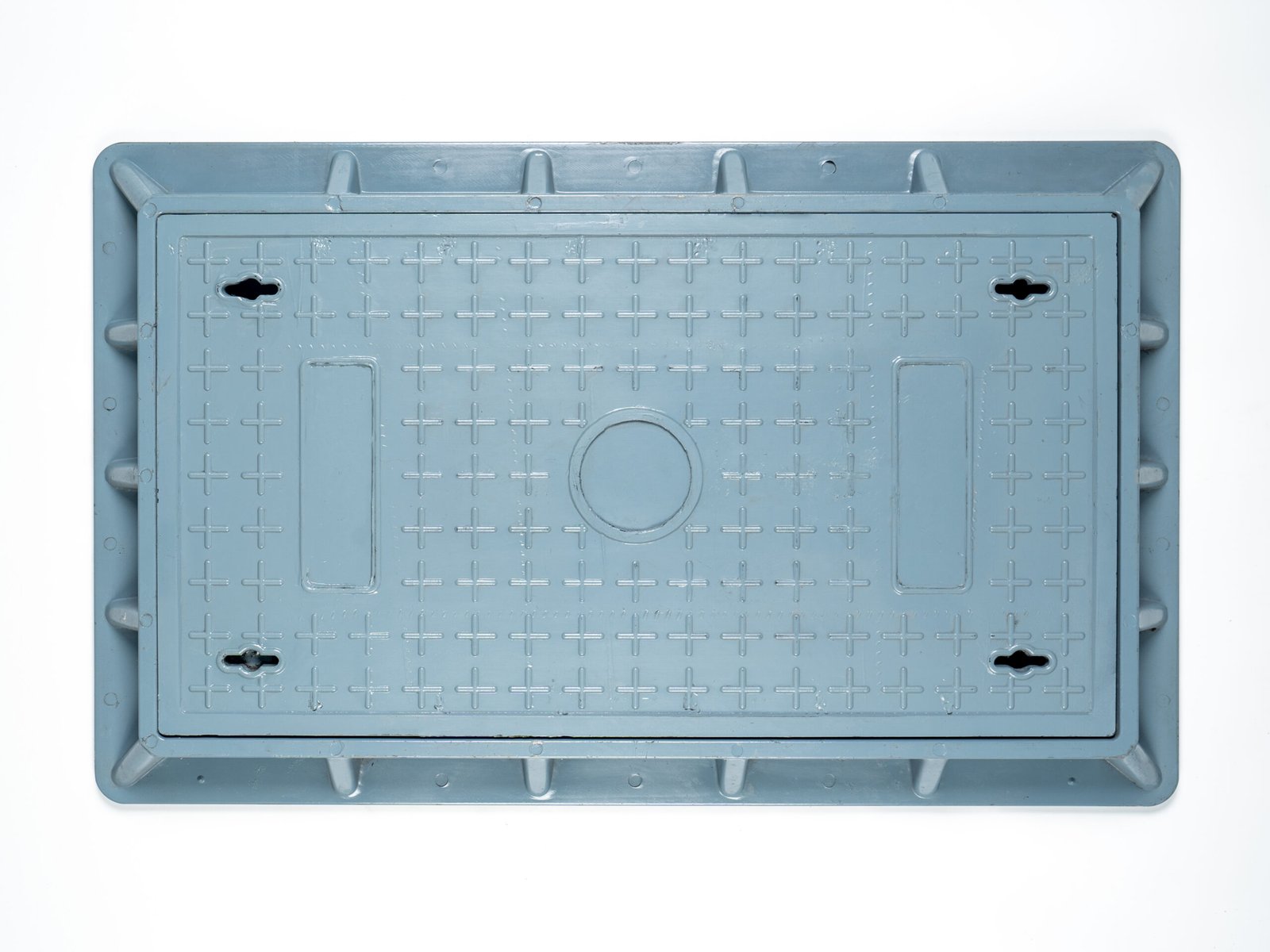

Specifications:

300×500–600×800mm

Load Rating:

A15