With the increasing improvement of urban infrastructure today, manhole covers, as an important component of the road system, directly impact traffic safety and municipal maintenance efficiency. Traditional covers often face problems during use such as insufficient load-bearing capacity, noise generation, and poor anti-theft performance, while ordinary cast iron covers have a relatively short service life due to unstable material properties. The Luzhongbao Ductile Iron Ordinary Square Manhole Cover, based on the material advantages of ductile iron and precise structural design, successfully overcomes the technical defects of traditional covers through scientific stress analysis and innovative manufacturing processes, and has now become the ideal choice for fields such as municipal engineering and park construction.

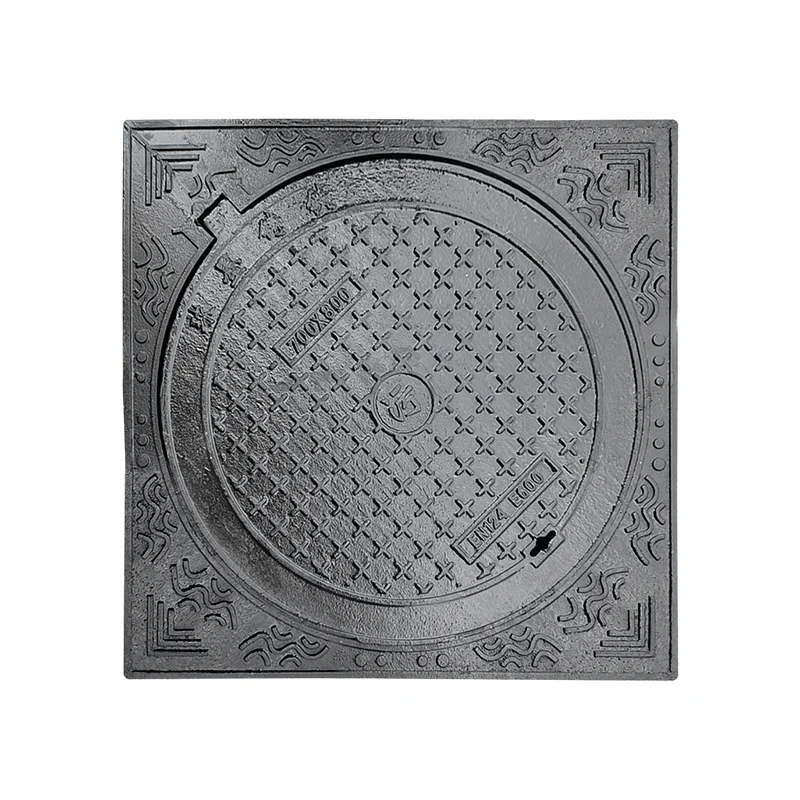

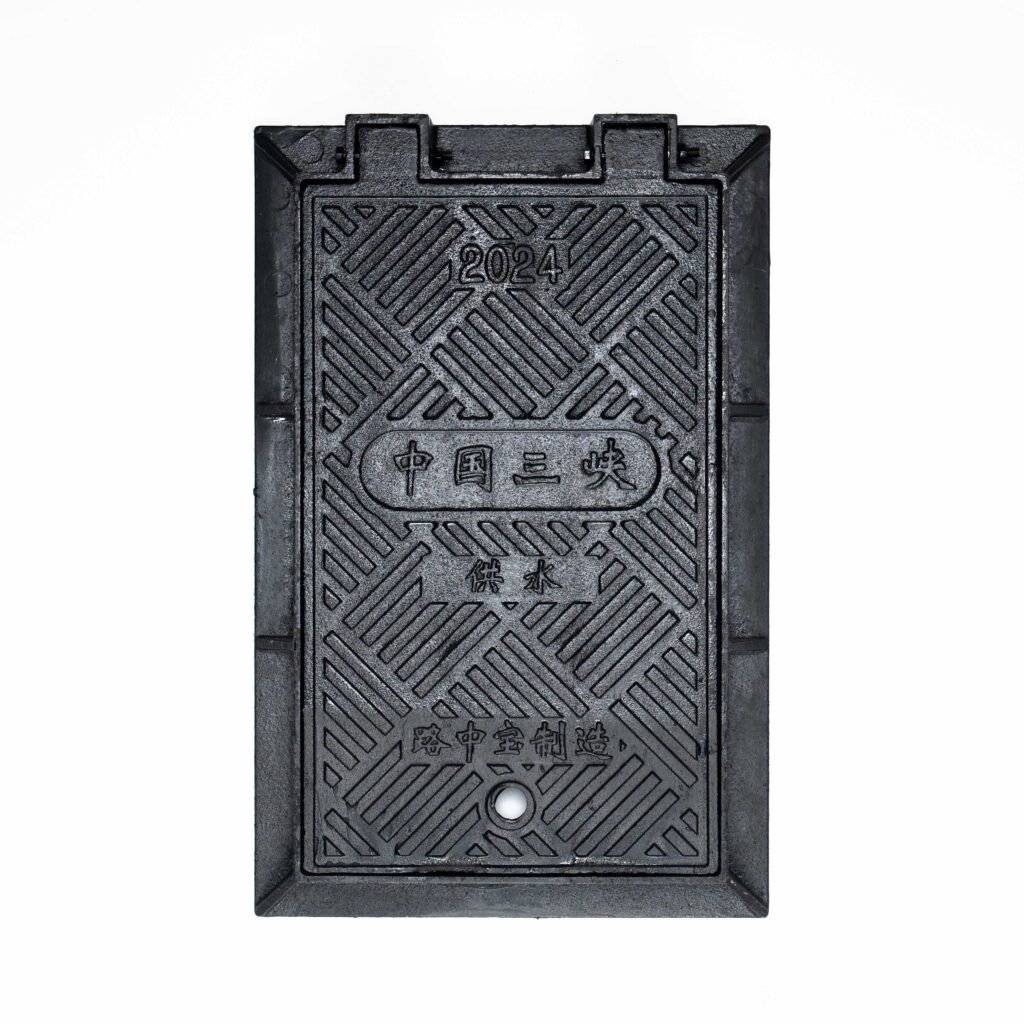

This product strictly complies with the GB/T 23858-2009 standard and is precision-cast using QT500-7 grade ductile iron. The square structure design keeps it parallel to road boundaries like curbs, ensuring both installation aesthetics and convenient construction positioning. The cover surface features a raised anti-slip pattern design, with a friction coefficient exceeding 80 BPN, and is treated with hot-dip galvanizing, with a zinc layer thickness of 70μm, ensuring long-term durability in humid environments. The unique structural design enables loads to be evenly distributed, effectively avoiding stress concentration phenomena and significantly improving the product's service life.

Material Advantages and Process Innovation

The Luzhongbao Square Cover selects QT500-7 ductile iron material. Its unique spheroidal graphite microstructure gives the material excellent mechanical properties. Tensile strength exceeds 500 MPa, and elongation exceeds 7%, combining high strength with good toughness. This material characteristic enables the product to withstand D400 grade loads, fully meeting the usage requirements for urban roads. The casting process uses advanced resin sand molding technology and an intelligent control system, ensuring precise product dimensions, a smooth surface, and a dense, uniform internal structure.

Structural Design and Performance Characteristics

The internal structure of this square cover is optimized through Finite Element Analysis, adopting a crisscrossing reinforcement rib layout to form a stable spatial load-bearing system. The four corners use a rounded transition design, with additional ribs installed internally, significantly improving impact resistance. Tested by professional institutions, the load-bearing capacity of this cover reaches the D400 standard, with a test load exceeding 400 kN. The unique edge design ensures a perfect fit with the frame, effectively preventing noise and bouncing during vehicle passage.

Safety Performance and Anti-Theft Design

The product surface uses a three-dimensional anti-slip pattern design, ensuring pedestrian safety in rainy or snowy weather. The anti-theft system uses concealed hinges and dedicated locks, requiring specific tools to open, fundamentally preventing theft. The mating surface between the cover and frame is precision-machined, ensuring stability and safety after installation. Additionally, the product is equipped with an anti-fall device, providing extra safety assurance for maintenance operations.

Durability and Anti-Corrosion Characteristics

Through dual protection of hot-dip galvanizing and epoxy asphalt coating, the product's corrosion resistance is significantly enhanced. The zinc layer forms a metallurgical bond with the substrate, effectively blocking the erosion of corrosive media. Verified by salt spray tests, the product's service life can exceed 30 years in harsh environments. The special surface treatment process also gives the product good UV resistance, preventing fading and aging during long-term use.

Construction Convenience and Economic Benefits

The modular design makes the installation process simple and efficient, with installation time per unit not exceeding 20 minutes. Precise dimensional control ensures a perfect fit with standard frames, requiring no on-site adjustments. From a whole-life-cycle cost analysis, the product's ultra-long service life and extremely low maintenance requirements reduce the comprehensive cost of use by over 35% compared to traditional products. According to engineering statistics, after adopting this cover, maintenance frequency is significantly reduced, effectively saving operation and maintenance costs.

Application Scenarios and Adaptation Performance

The square structure design enables this cover to better adapt to special spatial needs such as road boundaries and green belt edges. The product can be customized in different sizes and surface treatments according to actual needs, meeting the usage requirements of special environments. Its refined appearance design harmonizes with the surrounding environment, enhancing the overall landscape effect while meeting functional demands.

Summary

The Luzhongbao Ductile Iron Ordinary Square Manhole Cover, with its excellent material properties, scientific structural design, reliable safety performance, and significant economic benefits, has become the preferred solution for modern urban construction. This product not only solves the technical defects existing in traditional covers but also, with its innovative design concept and exceptional performance, provides reliable assurance for the safe operation of urban infrastructure. Choosing this product means injecting lasting quality assurance and value return into the engineering project, which is the fundamental reason for its continued recognition in the market competition.