In the construction of urban drainage systems, storm drain grates, as crucial facilities for road surface drainage, directly impact drainage efficiency, road safety, and municipal maintenance costs. Traditional storm drain grates often suffer from problems such as insufficient load-bearing capacity, susceptibility to clogging, difficulty in opening, and poor durability, while ordinary cast iron grates experience early damage or deformation due to unstable material properties. The Luzhongbao Ductile Iron Openable Storm Drain Grate, based on the material advantages of ductile iron and an innovative openable structural design, successfully solves the technical bottlenecks of traditional drainage facilities through scientific drainage hole arrangement and a reinforced support system, and has now become the ideal choice for projects like municipal roads and park drainage.

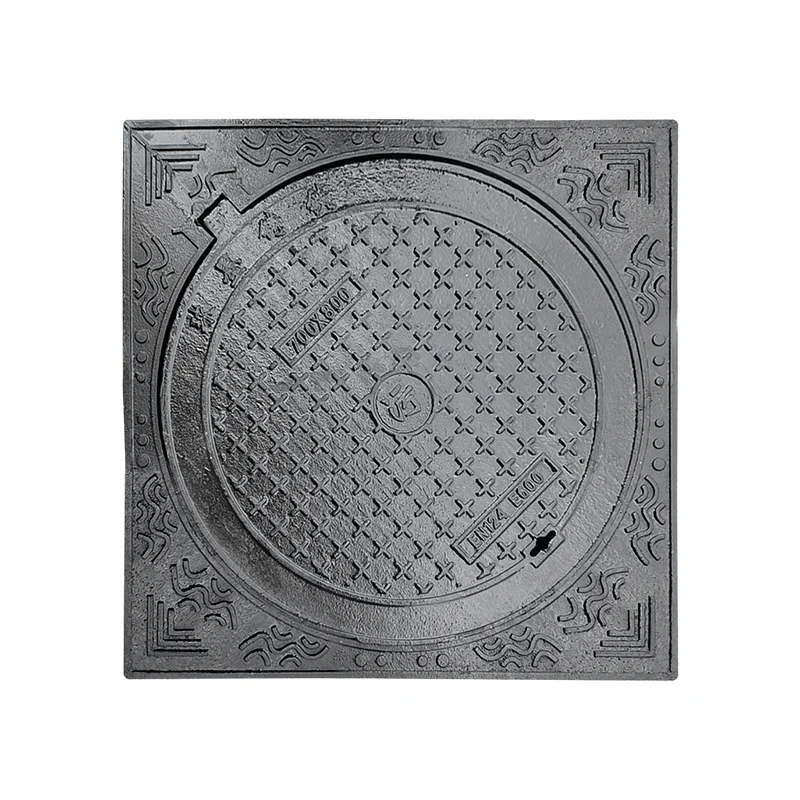

This product strictly complies with the GB/T 23858 standard and is precision-cast using QT500-7 grade ductile iron. The openable structure consists of three parts: base, fixed cover, and movable cover, enabling flexible opening and closing via a pin shaft. This design facilitates daily cleaning and maintenance while ensuring efficient construction and inspection. The grate surface features a deep anti-slip pattern design, with a friction coefficient exceeding 80 BPN, and is treated with hot-dip galvanizing, with a zinc layer thickness of 70μm, ensuring long-term corrosion resistance in humid environments. The internal three-dimensional reinforcement rib network and optimized drainage hole design significantly enhance load-bearing capacity and impact resistance while ensuring high drainage efficiency.

I. Material Advantages and Process Innovation

The core material of the Luzhongbao Storm Drain Grate selects QT500-7 ductile iron. Its spheroidal graphite microstructure gives the material excellent mechanical properties. Tensile strength exceeds 500 MPa, and elongation exceeds 7%, combining high strength with high toughness, resulting in a load-bearing capacity far exceeding ordinary cast iron. This material characteristic enables the product to withstand D400 grade loads, with a test load exceeding 400 kN, fully meeting the demands of urban arterial roads and heavy vehicle traffic.

The manufacturing process uses resin sand molding technology and an intelligent compression molding system, ensuring precise product dimensions and a dense internal structure. The unique openable structure connects the movable cover to the fixed cover via a pin shaft, allowing quick opening and closing without large machinery, significantly improving maintenance efficiency. Dual protection of surface hot-dip galvanizing and epoxy asphalt coating gives the product a corrosion-resistant service life exceeding 50 years, far surpassing the service life of traditional grates.

II. Structural Design and Functional Characteristics

1.Innovative Openable Structure:

The grate consists of three parts: base, fixed cover, and movable cover, which opens via rotation on a pin shaft. This design avoids the complexity of replacing the entire traditional grate and facilitates the cleaning of clogging debris, significantly reducing maintenance difficulty.

2.Efficient Drainage and Anti-Clogging Design:

The drainage hole layout is optimized through fluid dynamics simulation, using gradually expanding hole shapes and curved drainage channels to effectively increase the water flow area and reduce debris ingress. Actual measurements show drainage efficiency remains above 95% even under rainfall intensity of 150 mm/h, and it effectively intercepts debris like leaves.

3.Multiple Safety Protections:

Anti-theft: Built-in hinges and a dedicated locking system require specific tools to open, preventing illegal removal.

Anti-slip: The surface has raised 3mm patterns with a friction coefficient exceeding 80 BPN, ensuring pedestrian safety in rainy or snowy weather.

Anti-settlement: The frame is fixed to the road base with anchor bolts, preventing displacement caused by vehicle traffic or settlement around the manhole.

III. Load-Bearing Performance and Durability

The product load-bearing class reaches the D400 standard, with a test load exceeding 400 kN, capable of withstanding heavy vehicle traffic over 36 tons. The internal grid-pattern reinforcement rib layout forms a spatial load-bearing system, effectively dispersing loads and avoiding stress concentration. Verified by salt spray tests, the zinc layer forms a metallurgical bond with the substrate, improving corrosion resistance by more than three times, with a design life exceeding 30 years.

IV. Construction Convenience and Economic Benefits

Modular design improves installation efficiency by over 50%. The grate can be paved and rolled simultaneously with the asphalt road surface, requiring no concrete curing time. Installation time per unit does not exceed 30 minutes. From a whole-life-cycle cost analysis, the product's long service life and low maintenance requirements reduce comprehensive costs by 35%–40%. For example, in a Huangdao District renovation project, using similar grates reduced maintenance frequency by 80%, significantly saving maintenance funds.

V. Application Scenarios and Adaptation Performance

The product can adapt to various drainage scenarios such as municipal roads, expressways, and residential areas. Standard sizes like 750×500mm cover mainstream manhole needs, and surface treatment processes can be customized to suit special environments. Its compact structure and quick-opening feature make it particularly suitable for emergency drainage in areas with high rainfall frequency.

Summary

The Luzhongbao Ductile Iron Openable Storm Drain Grate, with its innovative openable structure, exceptional load-bearing performance, long-term durability, and construction convenience, has become the preferred solution for modern urban drainage construction. It not only solves the pain points of traditional grates regarding clogging, difficult maintenance, and short service life but also, through its modular design and multiple protective functions, provides reliable assurance for the efficient operation of urban drainage systems. Choosing this product means injecting lasting quality assurance and whole-life-cycle economic benefits into the engineering project, which is the core reason for its continued recognition in the market competition.