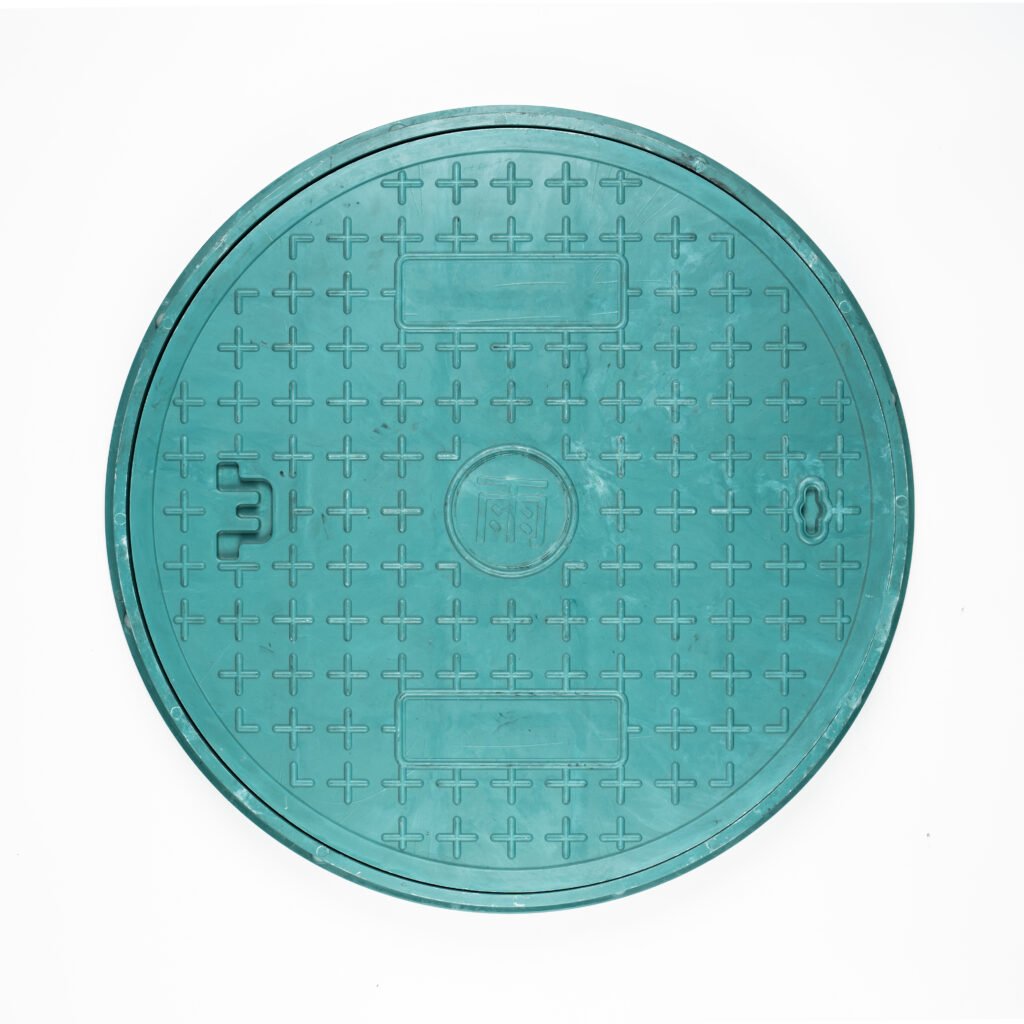

Why Luzhongbao 700×760×50 Composite Circular Well Has Become the Preferred Solution for Municipal Pipeline Network Engineering

With the increasing sophistication of urban underground pipeline network systems today, inspection wells, as critical nodes connecting various pipelines, directly impact the operational efficiency and service life of the entire pipeline network system through their performance quality. Traditional inspection wells commonly exhibit problems during long-term use, such as significant self-weight, insufficient corrosion resistance, and susceptibility to uneven settlement, while ordinary composite inspection wells often struggle to meet the load-bearing requirements of main roads due to inadequate structural strength. The Luzhongbao 700×760×50 Composite Circular Well, based on advanced materials science and structural engineering technology, successfully breaks through these technical bottlenecks through scientific dimensional design and innovative structural reinforcement, and is increasingly becoming the preferred solution in the field of municipal pipeline network engineering.

This composite circular well adopts an optimized structural design of 700mm inner diameter × 760mm outer diameter × 50mm wall thickness. This specification is the result of rigorous mechanical calculations and Finite Element Analysis, achieving the optimal balance between structural strength and material economy while ensuring sufficient internal operating space. The standard 50mm wall thickness, combined with the internally three-dimensionally distributed reinforcement rib network, forms an efficient spatial load-bearing system. The product is manufactured using high-performance composite materials, offering exceptional corrosion resistance, impact resistance, and structural stability. Its precise spigot-and-socket joint design ensures installation convenience and sealing reliability, which is the key to its widespread recognition in various municipal pipeline network projects.

Excellent Structural Performance

The core advantage of the Luzhongbao Composite Circular Well lies in its outstanding structural design. Through the standard 50mm wall layer and scientifically distributed reinforcement rib system, the well body achieves a ring stiffness of SN12.5 or higher, capable of withstanding dynamic loads generated by repeated heavy vehicle traffic. The unique structural design enables loads to be evenly transferred along the well wall, effectively avoiding stress concentration phenomena and ensuring structural integrity and stability are maintained during long-term use.

Superior Durability Assurance

The circular well manufactured from high-performance composite materials possesses excellent chemical corrosion resistance, effectively resisting long-term erosion from acids, alkalis, microorganisms, and wastewater in the soil. The product has a design service life exceeding 30 years and requires almost no maintenance throughout its entire lifecycle. This long-term reliability saves municipal departments significant maintenance costs and management resources, markedly reducing the whole-life-cycle cost.

Significant Construction Convenience

Engineering practice shows that the installation efficiency of this composite circular well is significantly improved compared to traditional products. Its precise spigot-and-socket joint design makes the installation process simple and fast. The modular structural characteristics make transportation and on-site assembly more convenient. The product weight is only 1/8 of a traditional concrete well, greatly reducing transportation and installation difficulties. The unique sealing system ensures the reliability of well body connections, effectively shortening the construction period.

Comprehensive Economic Benefits

From a whole-life-cycle cost perspective, this composite circular well demonstrates significant economy. Although the initial investment may be slightly higher than traditional products, its ultra-long service life, extremely low maintenance requirements, and saved installation costs make its comprehensive cost-effectiveness clearly superior to other solutions. Furthermore, its lack of scrap value effectively prevents theft, further reducing subsequent management costs.

Wide Application Adaptability

The innovative design of this composite circular well enables it to adapt to various engineering environment needs. Whether in urban arterial roads, expressways, industrial parks, or residential areas, it can provide reliable performance. Its standardized interface design can adapt to pipeline connections of different diameters. This wide application adaptability makes it an ideal choice for various types of municipal pipeline network construction.

Perfect Combination of Environmental Protection and Safety

The product is manufactured using environmentally friendly materials, and the production process meets green construction requirements. Its exceptional structural safety performance effectively ensures the long-term stable operation of underground pipeline networks. The innovative sealing system prevents groundwater pollution, fully reflecting the high importance modern engineering construction places on environmental protection and safety. The surface anti-slip design ensures the safe operation of maintenance personnel, providing reliable assurance for routine inspection and maintenance.

Summary

The reason why the Luzhongbao 700×760×50 Composite Circular Well has become the mainstream choice for municipal pipeline network engineering stems from its scientific dimensional design, reliable structural performance, convenient construction characteristics, and significant economy. This product not only solves the technical problems existing in traditional inspection wells but also provides a reliable solution for the construction of modern urban underground pipeline networks. Choosing this product means selecting a quality assurance and technical support for municipal engineering projects that stands the test of time, which is the fundamental reason for its continued recognition in the market competition.