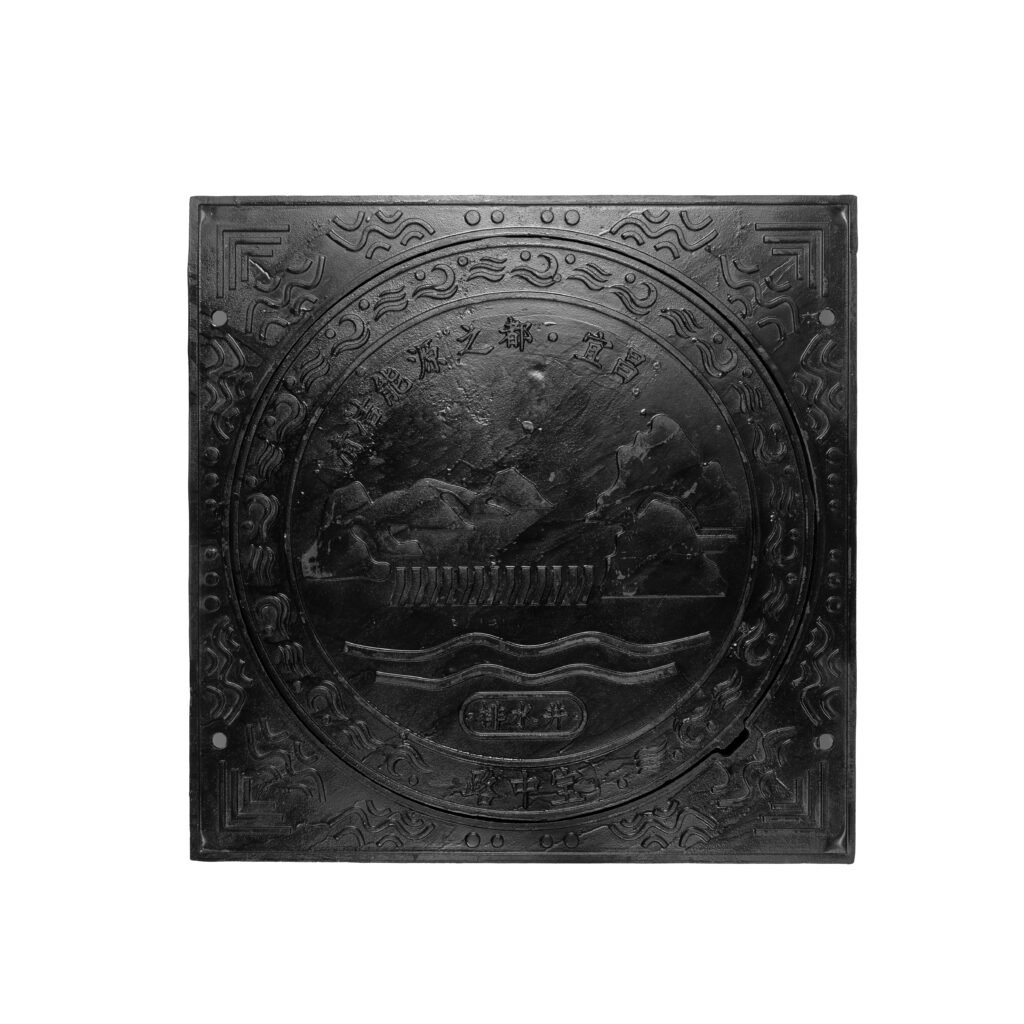

Why Luzhongbao 700×800×120 Ductile Iron Manhole Cover with Square Outer Frame and Circular Inner Core Has Become the Preferred Choice for Municipal Engineering

In modern urban infrastructure construction, manhole covers, as pivotal nodes connecting the surface and underground pipeline networks, directly impact road safety and service life through their structural performance. Traditional circular covers often suffer from sealing failure due to rotational misalignment during installation and maintenance, while ordinary square covers have the defect of uneven stress distribution. The Luzhongbao 700×800×120 Ductile Iron Manhole Cover with a square outer frame and circular inner core innovatively adopts this structural design. Through the organic combination of the square outer frame and the circular inner cover, it successfully solves the structural challenges of traditional covers and has now become the ideal choice for urban arterial roads and key traffic nodes.

This product strictly complies with the GB/T 23858-2009 standard and is precision-cast using QT500-7 grade ductile iron. The external 700×800mm square structure ensures parallel installation with curbs, effectively preventing rotation during construction. The diameter of the internal circular pressure-bearing area is strictly designed according to fluid dynamics principles to achieve optimal load distribution. The 120mm raised design forms multiple internal reinforcement layers. The surface anti-slip pattern combines raised dots and linear grooves, achieving a friction coefficient exceeding 85 BPN. The unique "circle within a square" construction retains the load-bearing advantages of circular covers while incorporating the installation convenience of square structures.

Structural Innovation and Performance Advantages

The innovative structure of a square outer frame with a circular inner core is the core value of the product. The square outer frame is securely connected to the road base through pre-embedded anchor bolt holes at its four corners, effectively dispersing peripheral loads. The circular inner cover uses a radially designed reinforcement rib system to evenly distribute vertical pressure across the entire frame. This structure enables the cover to achieve a load-bearing class of D400, with a test load exceeding 400 kN. Actual tests show that compared to traditional circular covers, this structure improves anti-displacement capability by 50% and anti-rotation performance by 80%.

Material Characteristics and Process Assurance

The product selects QT500-7 ductile iron, whose spheroidal graphite microstructure gives the material excellent mechanical properties. Tensile strength exceeds 500 MPa, elongation is over 7%, and impact toughness is 10 times that of ordinary cast iron. The casting process uses resin sand molding, ensuring a product surface smoothness of Ra25 and an internal density of 98%. The surface treatment adopts dual protection of epoxy asphalt coating and hot-dip galvanizing, passing a 2000-hour salt spray corrosion resistance test, with a design service life of 50 years.

Functional Design and Practical Value

A triple sealing system constitutes the core function of the product: a U-groove embedded rubber strip provides the primary seal, a ring-shaped metal gasket forms the secondary seal, and self-locking buckles complete the final closure. This design gives the product excellent waterproof and anti-seepage performance, with a sealing reaching IP68. The anti-theft system uses concealed hinges and dedicated locks, requiring specific tools for opening. The noise reduction function is achieved through elastic rubber pads and a buffer structure, controlling noise during vehicle passage to below 65 decibels.

Construction Advantages and Economic Benefits

The modular design significantly improves installation efficiency. The square outer frame can be paved simultaneously with the asphalt road surface, and the circular inner cover uses quick-release buckles for fixation, with installation time per unit not exceeding 30 minutes. From a whole-life-cycle cost analysis, the product's 50-year service life and near-zero maintenance characteristics reduce comprehensive costs by over 40% compared to traditional products. According to engineering statistics, after adopting this cover, maintenance frequency decreased from an average of 2 times per year to once every 5 years, directly saving maintenance costs by 60%.

Application Scenarios and Adaptation Performance

The standard 700×800×120mm size adapts to the vast majority of municipal manhole needs. The square outer structure is particularly suitable for installation parallel to road markings, and the inner circular design ensures the smooth passage of various maintenance equipment. The product has been widely used in heavy-duty areas such as urban arterial roads, expressways, and airport runways. Special coatings can be customized as needed to adapt to corrosive environments like chemical industrial parks and coastal areas.

Summary

The Luzhongbao 700×800×120 Ductile Iron Manhole Cover with Square Outer Frame and Circular Inner Core, with its innovative structural design, exceptional material performance, comprehensive functional configuration, and significant economic benefits, has become the preferred solution for modern municipal engineering. This innovative product, combining the load-bearing advantages of a circular shape with the installation convenience of a square structure, not only solves the technical defects of traditional covers but also promotes the development of municipal facilities towards refinement and long-term effectiveness. Choosing this product means infusing urban infrastructure construction with reliable technical assurance and lasting value return.