Why Luzhongbao 750×950×190 Ductile Iron Anti-Settlement Manhole Cover Has Become the Preferred Choice for Municipal Engineering

Against the backdrop of continuous upgrades in modern urban road infrastructure, manhole covers, as critical components connecting underground pipeline networks and road surface systems, directly impact road flatness, traffic safety, and maintenance costs. Traditional manhole covers commonly suffer from quality issues such as settlement, abnormal noise, and bouncing, while ordinary ductile iron covers often lack sufficient coordination with the road surface due to unreasonable structural design. The Luzhongbao 750×950×190 Ductile Iron Anti-Settlement Manhole Cover, based on innovative anti-settlement technology and optimized structural engineering, effectively transfers the pressure borne by the cover to the road structural layers through a special spigot-and-socket connection and wide-flange load dispersion design, significantly reducing the load on the manhole structure itself and fundamentally solving the problem of pavement settlement and damage around the manhole.

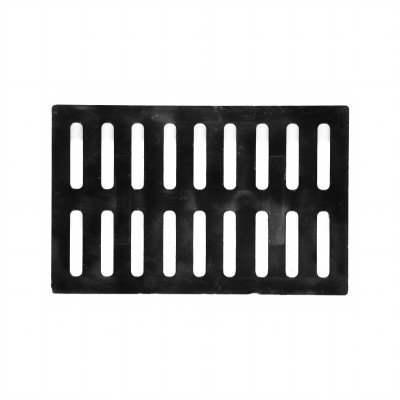

This product strictly complies with the GB/T 23858-2009 standard and is precision-cast using QT500-7 grade ductile iron. Its 750mm × 950mm rectangular size, combined with a 190mm reinforced height, and utilizing a U-groove embedded rubber strip and a triple sealing system, achieves multiple functions including shock absorption, noise reduction, leak prevention, and anti-theft. The cover surface is designed with raised anti-slip patterns (height ≥ 3mm), with a friction coefficient exceeding 80 BPN, ensuring traffic safety in rainy or snowy weather. Furthermore, the wide-flange structure allows the cover to tightly integrate with the asphalt pavement, enabling synchronous settlement with the road surface, avoiding the "belly button effect," and significantly improving road flatness and durability.

I. Structural Innovation: Load Dispersion and Anti-Settlement Design

The core advantage of the Luzhongbao Anti-Settlement Cover lies in its spigot-and-socket connection structure. By changing the traditional "plinth seating" connection between the frame and the manhole structure to a "spigot-and-socket" type, the cover load is dispersed to the road structural layers through the wide flange face, rather than acting directly on the brick manhole structure. This design can reduce the pressure on the manhole structure by over 60%, effectively preventing cracking and settlement of the surrounding pavement caused by load concentration. Additionally, the pre-set anchor bolt holes in the frame are fixed to the road base through anchoring, completely eliminating displacement or bouncing of the cover under vehicle traffic.

II. Materials and Performance: High Strength and Long-Term Durability

1.Advantages of Ductile Iron Material:

Uses QT500-7 grade ductile iron. Its spheroidal graphite microstructure gives the material excellent properties including tensile strength ≥ 500 MPa and elongation ≥ 7%. This material is not only high-strength and tough but also 30% lighter than similar gray cast iron covers, and can withstand test loads exceeding 400 kN (complying with the D400 pressure resistance grade), fully meeting the requirements for heavy vehicle traffic.

2.Corrosion Resistance and Durability:

The surface is treated with hot-dip galvanizing or epoxy asphalt coating (zinc layer thickness ≥80μm). Its corrosion resistance far exceeds that of ordinary cast steel. This three-layer anti-corrosion system can effectively resist groundwater, soil acid-base corrosion, and microbial erosion, enabling the cover to achieve a C5 corrosion resistance grade in underground environments. Compared to ordinary paint treatment, its anti-corrosion life is extended to over 15 years.

III. Multi-functional Integration: Safety, Quietness, and Anti-Theft

1.Five Protective Features:

Anti-noise: The contact surface between the cover and frame is machined and embedded with a T-shaped synthetic rubber strip, eliminating traffic noise through elastic buffering.

Anti-theft: Uses concealed hinges and a dedicated locking system, requiring special tools to open, fundamentally preventing theft.

Anti-fall: Built-in anti-fall grid (load-bearing capacity ≥100 kg), combined with an identification nameplate on the cover, enabling intelligent "one-well-one-file" management.

2.Environmental Protection and Adaptability:

The wide-flange design prevents rainwater penetration into the road base, protects the interface between the frame and asphalt, and reduces surrounding water accumulation. Some projects can customize patterns with regional characteristics to enhance the city's cultural image.

IV. Construction Convenience and Economic Benefits

Modular design improves installation efficiency by over 50%. The cover can be paved and rolled simultaneously with the asphalt road surface, requiring no concrete curing time. Installation time per unit does not exceed 30 minutes. From a whole-life-cycle cost analysis, although the initial investment is about 20% higher than ordinary covers, its ultra-long service life and near-zero maintenance characteristics can reduce comprehensive costs by 30%–40%. For example, after Yidu City replaced 1016 similar covers, the maintenance frequency around manholes decreased by 80%, significantly saving maintenance funds.

V. Application Scenarios and Engineering Verification

This product has been widely used in municipal engineering projects across many regions in China. Project tracking indicates that after use, the coincidence rate of cover and road surface flatness exceeds 95%, and vehicle traffic comfort is significantly improved. Its 750×950×190mm specification adapts to the vast majority of municipal manhole needs, being particularly suitable for heavy-duty areas like urban arterial roads, expressways, and airport runways.

Summary

The Luzhongbao 750×950×190 Ductile Iron Anti-Settlement Manhole Cover, with its innovative spigot-and-socket structure, exceptional load dispersion capacity, long-term durability, and construction convenience, has become an indispensable key component in modern urban road construction. It not only solves the pain points of traditional covers regarding settlement, noise, and theft but also provides lasting value for municipal engineering through its whole-life-cycle cost advantages. Choosing this product means practicing the concepts of urban safety, environmental protection, and sustainable development, which is the core reason for its widespread recognition in numerous key projects nationwide.